URobotech uzibophezele ekwakheni-ngabazauhlobo lwenyoni enkuluimikhiqizo,Ukusekela imikhiqizo yokuhambisa, isoftware yokuphathwa kweWarehouse Management System neminye imikhiqizo, futhi amabhizinisi ayo ahlanganisa izimboni eziningi. Iqembu layo lingenza futhi ngokwezifiso ukwakheka okungejwayelekile kwamakhasimende asuselwa ekucacisweni kwezimpahla. Phakathi kwabo,"I-Bull "Series Stacser Craneithuthukiswe ngokukhethekile futhi yakhelwe izinsiza ezisindayo zokulayisha, okuyintoingahlangana kahle futhi ngokusheshe ihlangabezane nezidingo zokufinyelela ezizenzakalelayo zemithwalo esindayo.

I-Zhou Weicun, umqondisi weSikhungo Sezobuchwepheshe Sezobuchwepheshe Sesibili se-ROngotech Ubuchwepheshe be-automation (suzhou) Co, Ltd

I-Zhou Weicun, umqondisi weSikhungo Sezobuchwepheshe Sezobuchwepheshe Sesibili se-ROngotech Ubuchwepheshe be-automation (suzhou) Co, Ltd

Muva nje, intatheli ye-Logistics Technology kanye nesicelo esixoxiwe uMnuz Zhou Weicun, umqondisi we-Second Engineering Technology Center of Robotech automation Technology (SUZHOU) Co, LTD, wambuza ukuthi angenise izici, kanye nezindlela zokuthuthuka zesikhathi esizayo ze-Hard Logistics Logistics.

Intatheli:Imboni ichaza kanjani "I-Hard Load Logistics"? Imiphi imikhiqizo ehambisanayo kaRobotech?

Zhou weicun:Njengamanje, ayikho incazelo ecacile ye- "Heavy Load Logistics" embonini. Emhlabeni jikelele, ngamazinga okulayisha, singabahlanganisa ne-European Pallet Standard UIC 335 ukumane uhlukanise izimpahla ezikhanyayo nezisindayo. Ngokwesibonelo,Amaphakethe Ajwayelekileibekwe ngokungahambisani kuma-pallet angathwalaI-1000kg yezimpahla ezijwayelekile,Amaphakethe ajwayelekile futhi afulethiniingathwalaI-1500KG, futhiama-compact and pallets ajwayelekileingathwalaI-2000kg.

Ngokuthuthuka okusheshayo komkhakha wezinto ezithengiswayo, isidingo se-Warehouse automation kanye ne-intellince emidlalweni ehlukahlukene ekwanda usuku nosuku. Ngokuya ngesisindo nosayizi wezimpahla, ukuphatha kanye nemishini yokugcina impahla esetshenzisiwe ingahluka, kanye nemiklamo yesakhiwo kanye nezidingo zezakhi zemishini yokufaka nakho kungahluka. Lapho ama-logistics eyeditors enza ukuhlelwa kohlelo, azoqhuba amakhono okucwaninga kwemishini ehambisanayo kanye ne-Design Design esekelwe ezinhlelweni zokuhlela ezihlukile.

Imikhiqizo yeRobotech Crane Crane isiza ukuthuthukisa i-Hard Load Logistics automation

Imikhiqizo yeRobotech Crane Crane isiza ukuthuthukisa i-Hard Load Logistics automation

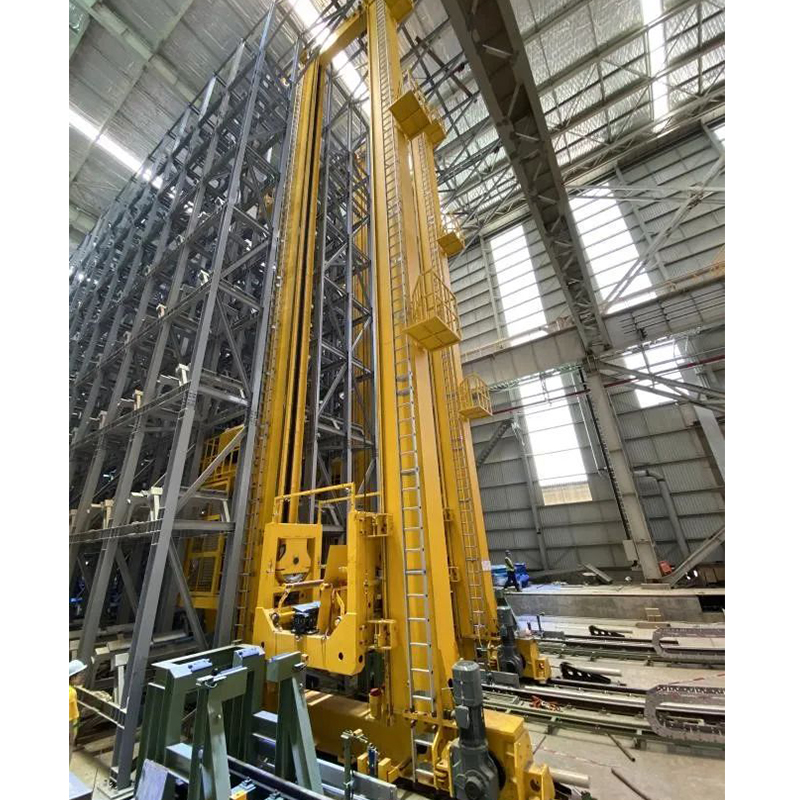

I-Stacker Crane ngumkhiqizo we-robotech. Njengamanje, inochungechunge lwemikhiqizo eyisikhombisa: "Idube","Ingulule","Ingonyama","Uhlobo lwengwe","Indlulamithi"," Bull", futhi"Izinhlanzi ezindizayo". Phakathi kwazo, the"I-Bull "Series Stacser Craneithuthukiswe ngokukhethekile futhi yakhelwe ukuthola izinto ezisindayo zokulayisha, ngobubanzi bomthwalo womthwalo we5t to 30t, okungakwazi ukufeza kahle futhi ngokusheshe ahlangabezane nezidingo zokufinyelela ezizenzakalelayo zemithwalo esindayo. Lapho imfanelo yezinto ezibonakalayo idlula uhla lwe-bearing lweI-30T, isikhungo se-robotech Austria R & D singakwaziYenza ngokwezifiso ukwakheka okujwayelekilekumakhasimende asuselwa ekucacisweni kwezimpahla.

Obikayo: Yiziphi izidingo ezikhethekile zokutholwa kwezinto ezisindayo zomthwalo we-Stacker Crane imishini?

Zhou weicun: Imvamisa, lapho isisindo sezimpahla sikhonaKukhulu kakhulu, kunezidingo eziphakeme zesakhiwo sensimbi, ukulayisha ipulatifomu, kanye neForks of the Stacser Crane, okwenza umklamo ube nzima ngokwengeziwe.Izici ezithile nezidingo zinjengokulandelayo:

1). Izinto zokwakha. Uma kuqhathaniswa nokukhanya okukhanyayo kwama-cranes, imishini esindayo yokulayisha inesisindo esikhulu sonke, futhi umklamo wesakhiwo sensimbi ngokuphelele udinga ukusetshenziswa kwezinto ezibonakalayo eziphezulu ezibonakalayo.

2). Ukwakheka. Lapho ukuphakama nesisindo se-crane ye-Stacser kukhulu, ikholomu idinga ukuqoqwa futhi ifakwe ngamapuleti ensimbi. Izitimela zensimbi ye-Flat zensimbi noma ojantshi be-T-khejini obunjiwe zidinga ukufakwa kukholomu. Ngemuva kwesakhiwo sensimbi esemqoka seldid, ukwelashwa okusiza ngcindezi kudinga ukwenziwa; Indlela yokuhambisa ekuphakamiseni yenzelwe amasethi amaningi ama-pulleys ashukumisayo ukunciphisa amandla entanjeni yensimbi yensimbi, futhi anciphise ukunwetshwa kwentambo yensimbi yensimbi, futhi kwandise impilo yenkonzo yentambo yensimbi yensimbi; Lapho uklama, kungenzeka ukuthi ucabangele ukwengeza idivaysi yokunyakazisa ngentambo ye-wire anti isuselwe ekuphakameni kwemishini.

3). Ukuphepha.Lapho ukhetha amamodeli, ukuphepha kwemishini yokulayisha esindayo kufanele kucatshangelwe, futhi ukwakheka okwenziwe ngezifiso kwendlela ehlanganayo kuyadingeka ukusebenzisa amandla amakhulu okubopha ukubopha umzimba womzimba kanye nojantshi wekholamu; bese ukhetha idivaysi efanelekayo ye-Hydraulic Buffer. Ekuklameni kukagesi, ukuvumelanisa kwe-Dual drive kanye nokulawulwa kwe-anti Shake kwamukelwa ukuqinisekisa ukusebenza okusebenzayo nokuzinzile kwemishini; Sebenzisa imisebenzi efana nokuqashelwa kwekheli ezenzakalelayo nokugwema ukushayisana ukuthuthukisa ukuphepha kwemishini yokuphatha nokugcina.

4). Ukusetshenziswa kwamandla.Qhathanisa nemishini yokulayisha ekhanyayo, amandla e-motor we-terum-dut furter cranes ephakeme, futhi amandla we-drive nawo anda kakhulu, okudinga ukulondolozwa kwamandla okukhulu; Njengamanje, imishini yethu yokusebenzisa amandla amandla ingafinyelela ezingeni le-IE4 (elihambelana nezinga elijwayelekile likazwelonke elijwayelekile lamandla).

Obikayo: Kususelwa ezidingweni ezikhethekile ezingenhla, yiziphi izingqinamba ezibalulekile ezidinga ukunakwa lapho zihlela futhi ziklama izisombululo ezisindayo zokulayisha ezisebenza ngokuzenzakalela ngokusekelwe kuma-cranes afakiwe?

Zhou weicun: Kuhlelo oluzenzakalelayo lwe-Load Logistics, luqukethe ikakhulukazi imishini ehlakaniphile enobuhlakani njengeIzinduna ezinamandla, ama-cranes aphathekayo asebenza kanzima, Imigqa Esebenzayo Esebenzayo Yokuhambisa, Ama-RGVs, futhiIsoftware Yokulawula Ukuphathwa Kwama-Intelligent. Ukuqinisekisa ukusebenza okuzinzile, okuthembekile, nokusebenza kahle kohlelo lwe-Umba lapho kufakwa umthwalo omkhulu, izidingo eziphakeme zibekwe emandleni enhlaka, ukunemba kokukhiqiza, kanye nokusebenza okuphelele kwemishini yesoftware kanye ne-charper cranes. Ngokuvamile, abahlinzeki bezinto zokusebenza bavame ukukuthola kunzima ukuxazulula izinkinga ezihlobene lapho zingena emkhakheni wemithwalo esindayo.

Uma kuqhathaniswa nemishini engasindi, ama-cranes aphathekayo asesindayo anezindleko eziphakeme zokukhiqiza nezindleko zokufaka

Uma kuqhathaniswa nemishini engasindi, ama-cranes aphathekayo asesindayo anezindleko eziphakeme zokukhiqiza nezindleko zokufaka

Isibonelo, ekwakhiweni kweama-cranes aphathekayo asebenza kanzima, qhathanisa nemithwalo ekhanyayo, ngenxa yezinto ezifana nesisindo nevolumu, imishini esezingeni eliphakeme idinga ukuba namandla aphezulu okulayisha ngenkathi uhlangabezana nejubane lokusebenza eliphakeme nokunemba. Lapho unikeza indawo yokugcina, kuyadingeka ukwaba ukwahlukaniswa kwezimpahla ezigabeni zokuqamba ngokufaneleYehlisa ukugxilawezimpahla ezigangeni nasemhlabathini okubangelwa ukugcinwa okuminyene.

Ehlelweni lokukhiqiza nelokukhiqiza lamamodeli asebenza kanzima, kuyadingeka ukucubungula ujantshi wekholomu, odinga ukunemba kwemishini ephezulu. Ikakhulu lapho ukuphakama kwemishini kuphezulu, ukuphambuka kwe-welding kwesitimela somhlahlandlela kungadala ukugqoka okukhulu nokuklebhula isondo lomhlahlandlela ngesikhathi sokusetshenziswa. Ngesikhathi senqubo yokuhamba, amakholomu amade angaba nezidingo ezithile zemishini yokuhamba. Uma ukucaciswa kwezinto ezisebenza kanzima kukhulu, kudingeka isikhala esikhudlwana ukuze kugcinwe. Ngesikhathi sokulayisha nokulayisha, imishini emikhulu yokuphakamisa iyadingeka, futhi imishini esezingeni eliphakeme nayo idinga ukususa isondo lomhlahlandlela ngaphambi kokufaka kabusha, okudinga izindleko zokukhiqiza eziphakeme kanye nokufaka uma kuqhathaniswa namamodeli wokulayisha.

Ehlelweni lokukhiqiza nelokukhiqiza lamamodeli asebenza kanzima, kuyadingeka ukucubungula ujantshi wekholomu, odinga ukunemba kwemishini ephezulu. Ikakhulu lapho ukuphakama kwemishini kuphezulu, ukuphambuka kwe-welding kwesitimela somhlahlandlela kungadala ukugqoka okukhulu nokuklebhula isondo lomhlahlandlela ngesikhathi sokusetshenziswa. Ngesikhathi senqubo yokuhamba, amakholomu amade angaba nezidingo ezithile zemishini yokuhamba. Uma ukucaciswa kwezinto ezisebenza kanzima kukhulu, kudingeka isikhala esikhudlwana ukuze kugcinwe. Ngesikhathi sokulayisha nokulayisha, imishini emikhulu yokuphakamisa iyadingeka, futhi imishini esezingeni eliphakeme nayo idinga ukususa isondo lomhlahlandlela ngaphambi kokufaka kabusha, okudinga izindleko zokukhiqiza eziphakeme kanye nokufaka uma kuqhathaniswa namamodeli wokulayisha.

I-Nanjing yazisa imishini yokugcina (iqembu) Co, Ltd

Ucingo lweselula: +8625 52726370

Ikheli: No. 470, Yinhua Street, Jiangling District, Nanjing CTIY, China 211102

Iwebhusayithi:www.inforfor.com

I-imeyili:[I-imeyili evikelwe]

Isikhathi sePosi: Jun-14-2023