Special Price for Automation Consultants - Radio Shuttle – INFORM

Special Price for Automation Consultants - Radio Shuttle – INFORM Detail:

Overview

Product Analysis

①Functions

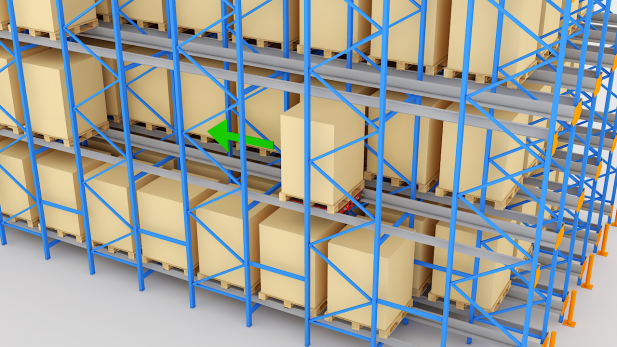

| 1 | Automatic single inbound | Accepting inbound instruction, shuttle lifts goods at the inbound end and places it on empty position then returns. |

| 2 | Automatic single outbound | After accepting outbound instruction, shuttle automatically takes the stored pallet in lane to outbound or shuttle mover. |

| 3 | Continuous inbound and

outbound |

For continuous inbound and outbound task in batch, the number to be operated can be set on remote control, mobile phone or

Tablet PC (optional) at one time, and continuous in & out work can be executed by one click. |

| 4 | Automatically switch A/B side | Shuttle can pick goods at both side of lane, no need to adjust orientation. |

| 5 | Pallet compatibility | Shuttle can be compatible with pallets in different model, please set in advance before operating at lane entrance. |

| 6 | Tally mode | Shuttle accepts instruction, automatically carries pallets in lane one by one into outbound end and arranges. |

| 7 | Count mode | Automatically count the number of lane’s pallet, and automatically count daily total inbound and outbound pallets. |

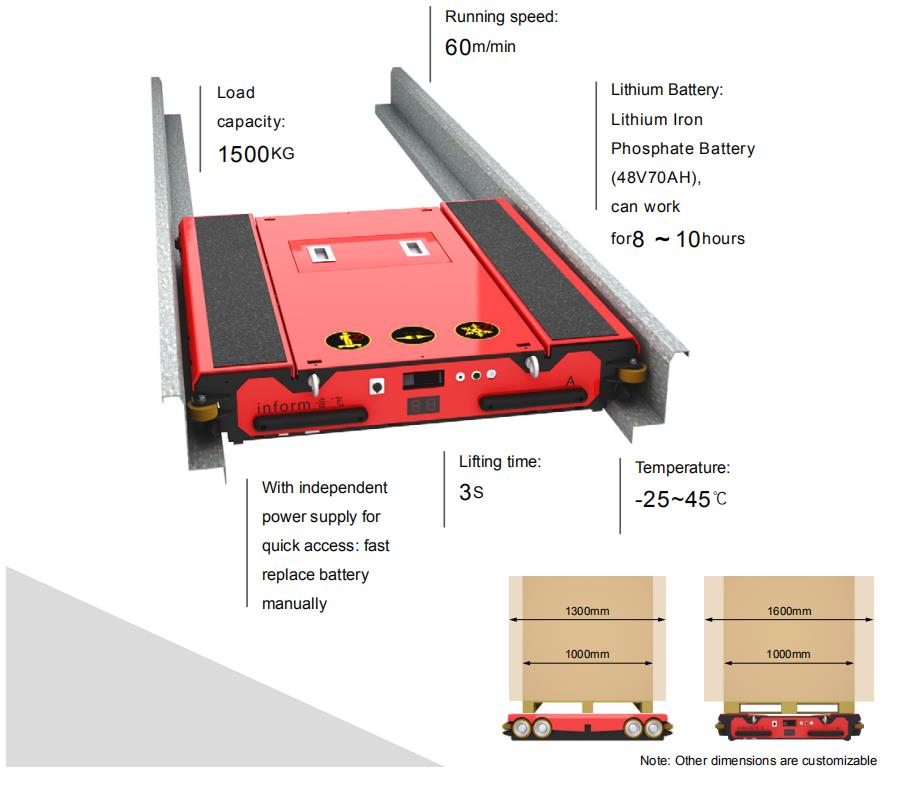

| 8 | Energy management | -Multi-level power threshold control, it goes back to start site after current task with prompting to replacement if low battery.

- In particular cases, shuttle can be charged out of line emergently. - Self-judging and self-charging on line (only in fully automatic operation) |

| 9 | Multipurpose remote control | Several shuttles can be operated by one remote control. |

| 10 | Seek for shuttle | Press one button on remote control to seek for shuttle and prompted by sound and light. |

| 11 | Recall manually | Recall to original position manually, by remote control, mobile phone or Tablet PC (optional), system instruction |

| 12 | Heartbeats function | Communicate to host computer control system in real time by heartbeat check to test online status (only full automation). |

| 13 | Emergency Stop | Emergency signal sent remotely when emergency, and shuttle stops instantly until emergency lifted.

It is capable of guaranteeing device or goods stop safely in maximal deceleration when it executes this instruction |

| 14 | Remote function | It is capable of updating and downloading program remotely (In Wi-Fi Network). |

| 15 | System monitoring | Monitoring system data in real time, and raising alarm in sound and light in abnormal status. |

②Features

◆Security guaranteed

When compared with drive-in racking, the structure is more stable.Operated by remote control or WCS, no need to drive into rack and reducing racking collision. Improve security productivity while allowing faster and more accurate storage of goods.

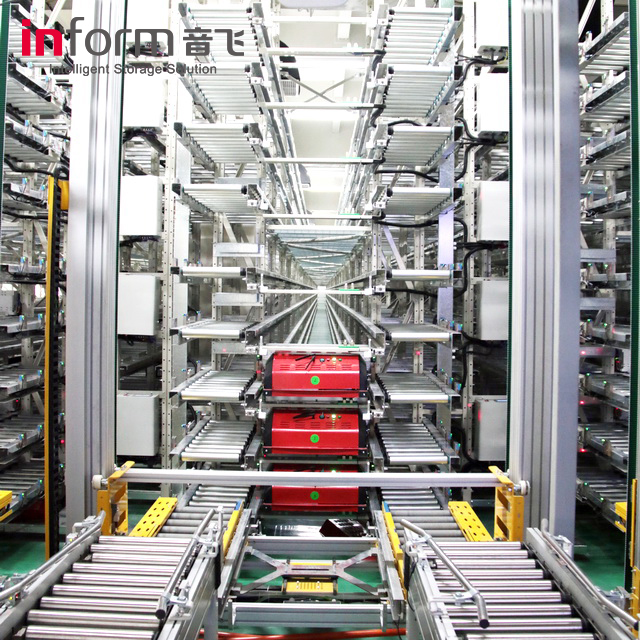

◆Enhance operation efficiency greatly

High working efficiency, automatic sorting, inventory. Flexible operation mode ,the goods access mode could be FIFO or FILO, which greatly reduces the operation waiting time.

◆High space utilization

Forklift aisle reduced when compared with other kinds of racks, special design could achieve the highest density storage.

◆Applicable industry

Cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

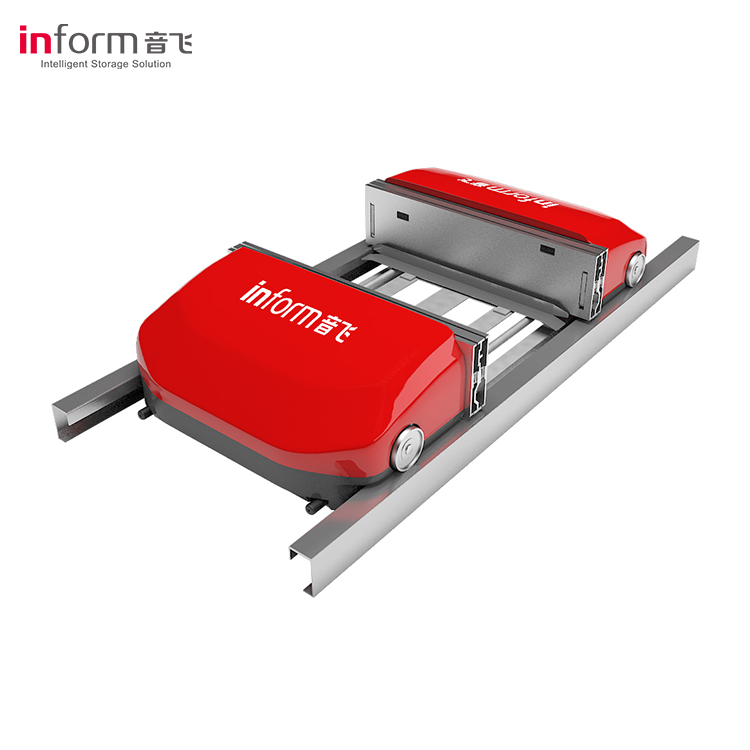

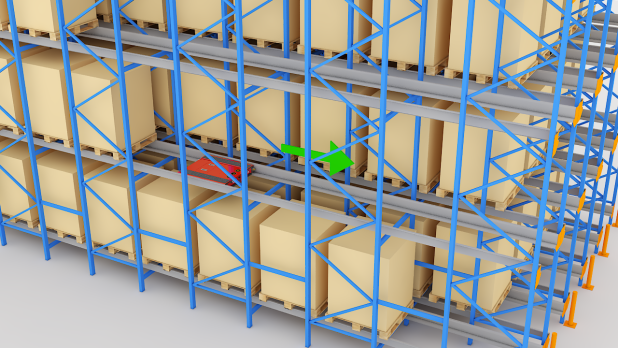

③Operation – Inbound

1.Place shuttle on the rail.

2. Press remote control inbound button.

3.Shuttle lifts the pallet, moves to .the deepest position,puts down the pallet.

4.Shuttle back to the front for new work.

Operation – Outbound

Shuttle executes same operations in reverse sequence.

④Design, Test &Warranty

Design

Free design could be provided with the following information.

Warehouse storage area Length____mm x Width____mm x Clear height___mm

Warehouse’s door position for loading and unloading goods

Pallet Length____mm x Width____mm x Height___mm x Weight_____kg.

Forklift minimal aisle width_____; Max lift height _____

Warehouse Temperature_____Degrees Celsius

Inbound and outbound efficiency: Quantity of Pallets per hour_____.

Test

Shuttle will be tested before delivery. Engineer could test the shuttle on-site or online.

Warranty

Warranty of one year. Fast response within 24 hours for overseas customer. Firstly test online and adjust ,if couldn’t repair online , engineer will go and solve the problems on site. Free spare parts will be supplied during the warranty time.

Project cases

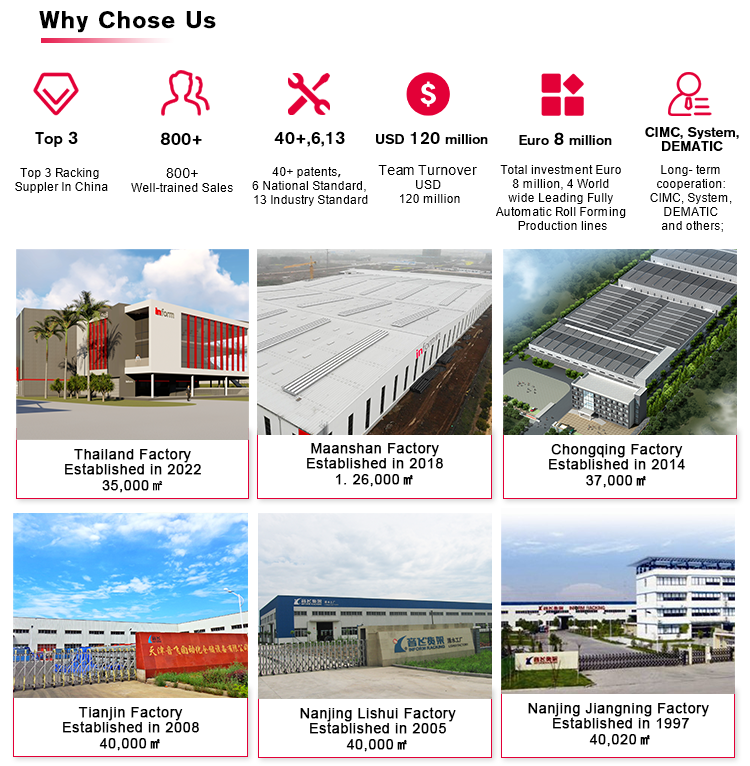

Why Choose Us

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed enterprise, specialized in the logistic storage solution field since 1997( 25 years of experience).

2. Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3. Inform owns 6 factories, with over 1000 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Special Price for Automation Consultants - Radio Shuttle – INFORM, The product will supply to all over the world, such as: Dubai, Mauritania, Jeddah, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.