Teardrop pallet racking is an essential component of modern warehouse and distribution center operations. Its unique design and versatile functionality make it a popular choice for businesses looking to optimize their storage solutions. In this comprehensive guide, we will explore the intricacies of teardrop pallet racking, its benefits, features, and applications, providing you with an in-depth understanding of why it stands out in the world of industrial storage.

Understanding Teardrop Pallet Racking

Introduction to Teardrop Pallet Racking

Teardrop pallet racking derives its name from the distinctive teardrop-shaped holes on its upright frames. These holes play a crucial role in the ease of assembly and adjustment of the racking system. Let’s delve into what sets this racking system apart from others.

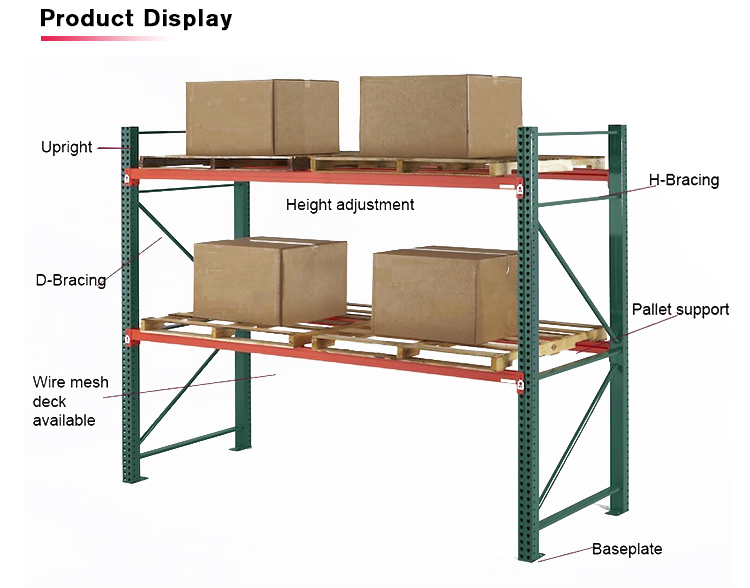

The Anatomy of Teardrop Pallet Racking

The core components of teardrop pallet racking include the upright frames, horizontal beams, and various accessories that enhance its functionality. The teardrop-shaped holes allow for quick and secure connection of beams to the uprights, ensuring stability and ease of adjustment.

Upright Frames

Upright frames are the vertical supports of the racking system. Made from high-strength steel, they come in various heights and load capacities to suit different storage needs. The teardrop holes on these frames facilitate the easy insertion of beams.

Horizontal Beams

Horizontal beams connect the upright frames and provide the actual shelving for pallets. These beams can be adjusted to different heights, making the system highly adaptable to different pallet sizes and storage requirements.

Accessories

Teardrop pallet racking can be customized with a range of accessories, including wire decking, safety bars, and row spacers. These accessories enhance the safety and efficiency of the racking system.

Benefits of Teardrop Pallet Racking

Ease of Installation

One of the standout features of teardrop pallet racking is its ease of installation. The teardrop-shaped holes and locking mechanism allow for quick assembly without the need for specialized tools, reducing labor costs and downtime.

Versatility and Adjustability

Teardrop pallet racking is designed for versatility. The adjustable beam levels allow for the storage of various pallet sizes and types, providing a flexible solution for changing inventory needs. This adaptability makes it suitable for a wide range of industries.

Compatibility

Another significant advantage is the compatibility of teardrop racking components across different brands. This interchangeability makes it easier to expand or modify existing racking systems without the need for complete overhauls.

Durability and Strength

Constructed from high-quality steel, teardrop pallet racking is built to withstand heavy loads and frequent use. Its durability ensures long-term reliability, making it a cost-effective investment for businesses.

Safety Features

Safety is paramount in any storage solution. The design of teardrop pallet racking includes secure locking mechanisms that prevent accidental beam dislodgement, enhancing workplace safety.

Applications of Teardrop Pallet Racking

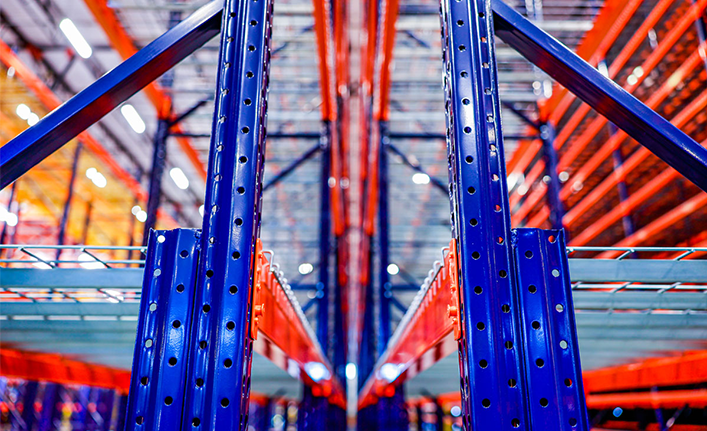

Warehousing

Teardrop pallet racking is widely used in warehousing for the storage of a variety of products, from raw materials to finished goods. Its ability to maximize vertical space and organize inventory efficiently makes it a preferred choice.

Distribution Centers

In distribution centers, where the rapid movement of goods is critical, teardrop pallet racking provides the necessary support. Its adjustable design accommodates different pallet sizes, ensuring smooth operations.

Retail Storage

Retailers use teardrop pallet racking in back-of-house storage areas to manage inventory. Its flexibility allows for the efficient organization of products, facilitating easy access and restocking.

Cold Storage

The durability and adaptability of teardrop pallet racking make it suitable for cold storage environments. It can handle the weight of heavy, temperature-sensitive products and withstand the conditions of refrigerated settings.

How to Choose the Right Teardrop Pallet Racking System

Assessing Your Storage Needs

Before investing in a teardrop pallet racking system, it is crucial to assess your storage needs. Consider the types of products you store, their dimensions, and weight. This assessment will help determine the appropriate load capacity and dimensions of the racking system.

Evaluating Space Constraints

Analyze the available space in your warehouse or storage area. Teardrop pallet racking is designed to maximize vertical space, so measure the height and floor space to ensure optimal configuration.

Considering Future Growth

When choosing a racking system, it’s essential to think about future growth. Teardrop pallet racking’s compatibility and adjustability allow for easy expansion, making it a scalable solution for growing businesses.

Consulting with Experts

Consulting with racking system experts can provide valuable insights into the best configuration for your specific needs. They can help you design a layout that maximizes efficiency and meets safety standards.

Installation and Maintenance

Installing Teardrop Pallet Racking

The installation of teardrop pallet racking involves a few key steps. Start by assembling the upright frames and securing them to the floor. Next, insert the horizontal beams into the teardrop-shaped holes and lock them in place. Ensure that all components are level and secure before loading pallets.

Regular Maintenance Practices

To maintain the integrity and safety of your teardrop pallet racking system, regular inspections are essential. Check for any signs of wear, damage, or misalignment. Tighten any loose bolts and replace damaged components promptly.

Safety Inspections

Conducting routine safety inspections can prevent accidents and prolong the lifespan of your racking system. Ensure that all safety features, such as locking mechanisms and safety bars, are functioning correctly.

Enhancing Efficiency with Teardrop Pallet Racking

Optimizing Storage Space

Teardrop pallet racking helps optimize storage space by utilizing vertical space efficiently. By adjusting beam levels, you can accommodate different pallet sizes, ensuring maximum use of available space.

Improving Inventory Management

The organized structure of teardrop pallet racking simplifies inventory management. Products are easily accessible, reducing the time spent locating and retrieving items. This efficiency boosts overall productivity.

Enhancing Workflow

A well-organized racking system enhances workflow by reducing congestion and improving the flow of goods. This streamlined operation leads to faster order fulfillment and improved customer satisfaction.

Conclusion

Teardrop pallet racking stands out as a versatile, durable, and efficient storage solution for various industries. Its unique teardrop-shaped design facilitates easy installation, adjustability, and compatibility, making it a preferred choice for businesses looking to optimize their storage operations. Whether for warehousing, distribution, or retail storage, teardrop pallet racking offers a robust and flexible solution that can adapt to changing needs and support long-term growth. Regular maintenance and safety inspections ensure the longevity and safety of the racking system, making it a reliable investment for any business. By understanding and leveraging the benefits of teardrop pallet racking, you can enhance your storage efficiency, improve inventory management, and ultimately, boost your overall operational productivity.

Post time: Jun-11-2024