1. Company profile

Guangzhou Pharmaceutical Co., Ltd. was established in 1951 with a registered capital of 2.227 billion yuan. It is the largest Sino-foreign joint venture pharmaceutical distribution enterprise in China. Guangzhou Pharmaceuticals owns an iconic brand that has been operating in the pharmaceutical wholesale and retail fields for nearly 70 years, and operates more than 50,000 products including medicines, medical devices, and health care products. It also provides value-added services in the pharmaceutical supply chain such as third-party pharmaceutical logistics, hospital pharmacy integration services, etc., and its operating performance has always ranked among the top five in the same industry in the country.

2. New logistics center completed

In recent years, the scale of the pharmaceutical circulation industry has grown steadily, and there has been a greater demand for terminal distribution.

As a well-known enterprise in China’s pharmaceutical industry, Guangzhou Pharmaceuticals is also facing such challenges and needs. Therefore, it has planned and built a high-automation and intelligent pharmaceutical logistics split-to-zero distribution center hub – Guangzhou Pharmaceutical Biomedical City Baiyun Base Logistics Project (Phase I) . It is understood that Guangzhou Pharmaceuticals has high expectations for the project, and plans to build it into a pharmaceutical terminal disassembly and sorting hub, to achieve a 4-hour service response target for terminal distribution in Guangdong Province, and to support an annual pharmaceutical distribution scale of 90 billion yuan.

3. ROBOTECH helps projects achieve intelligent upgrades

• Four Warehouse Centers

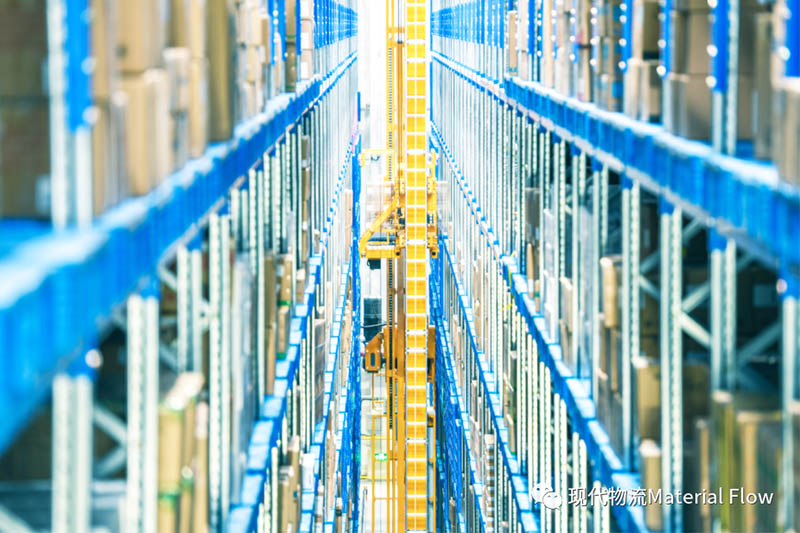

Guangzhou Pharmaceuticals chose to form a strategic alliance with the experienced ROBOTECH, and built four automated warehouses according to the characteristics of drug regulations. Inventory high-bay warehouses, side picking warehouses, and online picking warehouses are set as normal temperature warehouses, and the working environment temperature is 0~40℃; refrigerated high-bay warehouses are set as low temperature warehouses, and the working environment temperature is 2~8℃.

The automated warehouse includes AS/RS and related supporting systems, cold storage picking equipment systems, sorting and conveying systems and other systems. The AS/RS systems of the four automated warehouses centers are all provided by ROBOTECH Automation Technology (Suzhou) Co., Ltd. (full text: ROBOTECH), and a total of 21 sets of tracked aisle stacker crane systems have been planned, including more than 26,000 cargo spaces.

After the completion of the project, with the increase in logistics flow, the number of warehouse operators has been reduced by 50%, the annual throughput capacity has reached 24 million boxes, and the daily order processing capacity has reached 220,000 orders, with a significant breakthrough in work efficiency.

Not only has it become one of the modern pharmaceutical logistics distribution hubs with the highest automation, the strongest intelligence, and the most widely used technology in the country; It will also support the business development of Guangzhou Pharmaceutical Co., Ltd. in the next 10 years, and realize the logistics service needs of high automation, high intelligence and high efficiency in the pharmaceutical supply chain.

• Panther series

Based on the characteristics of massive SKUs and high throughput in the pharmaceutical distribution industry, ROBOTECH chose the Panther series for the AS/RS system of this project. This series of double-column stacker cranes has different models such as single-deep and multi-deep positions. It is fast, flexible and reliable. It is suitable for pallet storage systems with a load of less than 1,500kg and a height of 25m. The equipment can run at a speed of 240m/min and an acceleration of 0.6m/s2.

In response to the needs of the project, ROBOTECH further customized the project based on the selection. Adopt servo drive control, positioning accuracy. The response speed and handling efficiency are much better than the standard model. In addition, the servo drive has a good anti-shake function, which makes the stacker crane run more smoothly, and the safety and stability are significantly improved.

In response to the needs of the project, ROBOTECH further customized the project based on the selection. Adopt servo drive control, positioning accuracy. The response speed and handling efficiency are much better than the standard model. In addition, the servo drive has a good anti-shake function, which makes the stacker crane run more smoothly, and the safety and stability are significantly improved.

As a microcosm of the industry, this project promotes the coordinated, standardized and digitalized development of the pharmaceutical distribution supply chain. Since its delivery, it has won unanimous praise from customers. The relevant person in charge said that through the logistics solutions with partners such as ROBOTECH, it helped the logistics center to solve the particularity, diversity and complexity of products, and realized a new intelligent upgrade for a fast, stable and accurate pharmaceutical logistics system.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Aug-30-2022