In the world of warehouse storage solutions, pallet rack beams play a critical role. They are the horizontal bars that connect vertical frames and support the weight of pallets. Choosing the right type of pallet rack beam is essential for ensuring the safety, efficiency, and longevity of your storage system. In this guide, we will dive deep into the different types of beams for racking, their structures, advantages, and ideal applications. Whether you’re setting up a new warehouse or upgrading an existing one, understanding beam types is crucial for optimal racking performance.

Understanding Pallet Rack Beams: The Backbone of Storage Systems

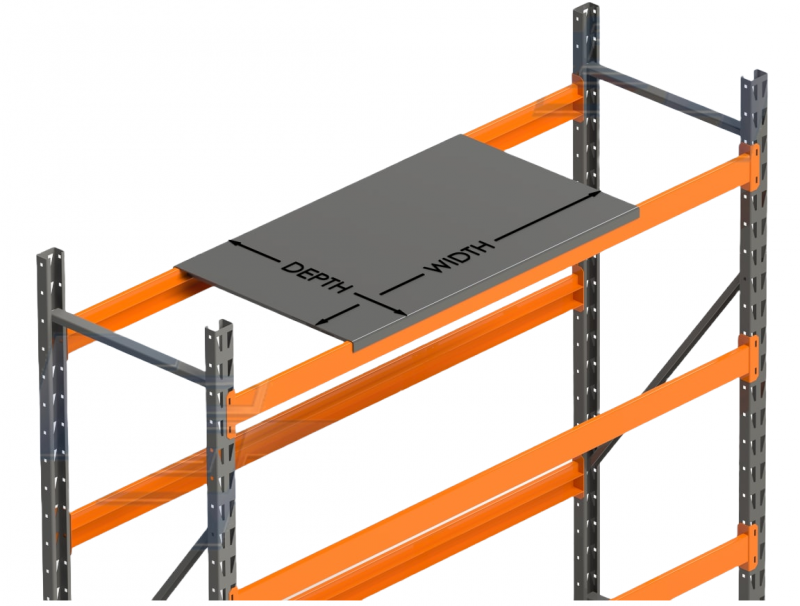

Pallet rack beams are more than just steel bars; they are the foundation upon which warehouse logistics rest. A pallet racking system without the right beams risks collapse, inefficiency, and even safety hazards. Beams must match both the weight capacity and the specific needs of the goods being stored. Factors such as beam length, depth, profile, and connection type all influence the system’s overall performance. Without proper beams, even the strongest uprights cannot maintain stability. Therefore, knowing the different types of pallet rack beams becomes a prerequisite to a well-organized, safe, and durable storage solution.

The Main Types of Pallet Rack Beams

When it comes to choosing pallet rack beams, you will generally encounter several main types, each with specific designs suited for different purposes. Let’s explore these options in detail:

1. Box Beams

Box beams are among the most common types used in industrial racking. These beams are rectangular or square in shape, providing exceptional load-bearing capacity and structural integrity. The closed-tube design reduces twisting and sagging under heavy loads.

Advantages:

-

Excellent strength-to-weight ratio

-

High resistance to torsion and bending

-

Suitable for heavy-duty applications

Ideal for: Heavy industrial storage, automotive parts, and bulk storage warehouses.

2. Step Beams

Step beams feature a recessed ledge along the top inside edge of the beam. This ledge is designed to support decking materials such as wire mesh decks, wooden panels, or steel decks.

Advantages:

-

Versatile support for different decking types

-

Easy to install accessories like safety bars

-

Smooth load distribution across shelves

Ideal for: Warehouses needing customized shelving solutions and frequent reconfigurations.

3. Structural Beams

Structural beams are manufactured from hot-rolled steel, making them stronger and heavier than roll-formed beams. They are typically bolted rather than clipped into place.

Advantages:

-

Extreme durability and impact resistance

-

Excellent for high-traffic, forklift-heavy areas

-

Withstands abuse better than standard beams

Ideal for: Environments where forklifts often interact with racking structures, such as cold storage or heavy manufacturing plants.

4. Roll-Formed Beams

Roll-formed beams are made from cold-rolled steel, creating a lighter, more cost-effective option. They are usually adjustable, offering flexible reconfiguration without the need for bolts.

Advantages:

-

Lightweight and easy to handle

-

Economical for medium to light-duty applications

-

Adjustable beam heights

Ideal for: Dynamic inventory environments with frequent SKU changes.

5. Z-Beams

Z-beams, named after their Z-shaped profile, are often used in specialized applications like carton flow racks or pick modules.

Advantages:

-

Efficient space utilization

-

Perfect for small, lightweight items

-

Allows sloped shelves for gravity flow setups

Ideal for: E-commerce fulfillment centers, retail warehouses, and distribution hubs with high-turnover items.

Comparative Table of Pallet Rack Beams

| Beam Type | Load Capacity | Material | Best For | Key Features |

|---|---|---|---|---|

| Box Beam | Heavy-duty | Closed steel tube | Automotive parts, bulk storage | High torsional resistance |

| Step Beam | Medium to Heavy | Roll-formed steel | Versatile shelving | Supports decking materials |

| Structural Beam | Heavy-duty | Hot-rolled steel | Forklift-heavy areas | Impact resistant |

| Roll-Formed Beam | Light to Medium | Cold-rolled steel | Dynamic inventory | Lightweight and adjustable |

| Z-Beam | Light-duty | Roll-formed steel | Carton flow, pick modules | Gravity flow capabilities |

Frequently Asked Questions About Pallet Rack Beams

What factors should I consider when selecting a pallet rack beam?

Several important factors come into play:

-

Load capacity: How much weight each beam level must hold.

-

Beam length: The span between uprights based on pallet size.

-

Material: Whether you need the durability of structural steel or the flexibility of roll-formed designs.

-

Connection type: Bolted or teardrop-style clip-in connections.

How do I know if my beam is properly installed?

Proper installation requires that beams are securely fastened to the upright frames with locking mechanisms engaged. Always verify the locking clips are properly inserted, and the beam is level with no visible sag. Regular inspections are critical to maintaining system integrity.

Can I mix different types of beams in one racking system?

Although technically possible, it is not recommended unless specifically engineered for that purpose. Different beam profiles have different load-bearing characteristics, and mixing them could lead to imbalances, decreased stability, and potential safety hazards.

Why Choosing the Right Pallet Rack Beam Matters

Investing time and effort in choosing the correct pallet rack beam offers numerous long-term benefits. Firstly, it enhances warehouse safety by preventing potential collapses. Secondly, it improves operational efficiency by allowing better organization and access to inventory. Thirdly, using the right beams minimizes maintenance costs and extends the life of the entire racking system.

Choosing the wrong type, on the other hand, can result in frequent damage, inefficient space usage, and even legal liabilities due to workplace accidents. Therefore, partnering with experienced warehouse planners or racking engineers during the selection phase is often worth the investment.

Post time: Apr-29-2025