The ceramic industry has a long development history and cultural heritage in China. Its main production areas are distributed in Jingdezhen, Pingxiang, Liling and other places. The current overall market size is about CNY 750 billion; Facing the pain of intellectual transformation and industrial transformation, Inform Storage and a ceramic enterprise in Jingdezhen jointly built an intelligent warehousing system, which enabled the rapid development of its production management, warehousing operations and services.

1. Project Overview

- 10 intensive warehouses

- 5 sets of four-way radio shuttle system for pallet

- 5 sets of four-way multi shuttle system for box

- 10 sets of attic shuttle system

- 10 four-way radio shuttles for pallet

- 20 four-way multi shuttles for box

- 10 attic shuttles.

- WMS system & WCS system

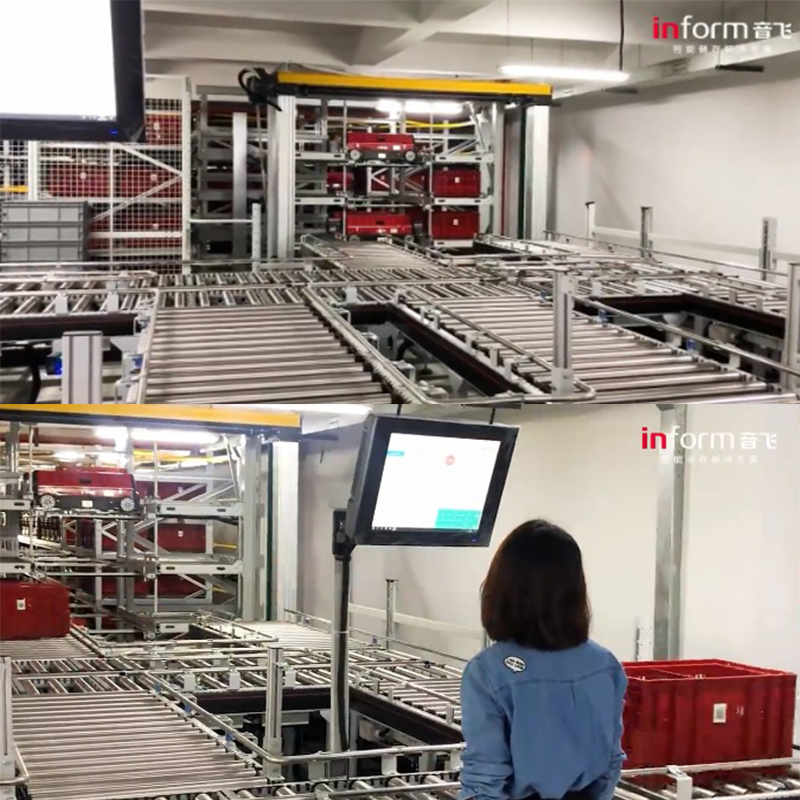

There are 10 intensive warehouses in the ceramic project, and the overall design scheme includes 5 sets of four-way radio shuttle system for pallet, 5 sets of four-way multi shuttle system for box, and 10 sets of attic shuttle system; A total of 10 four-way radio shuttles for pallet, 20 four-way multi shuttles for box, and 10 attic shuttles. The intelligent software system includes WMS system and WCS system.

2. Solution

Four-way radio shuttle system

5 intensive warehouses adopt the four-way radio shuttle system solution, each intensive warehouse has 2 shuttles and four mother lanes; a total of 10 four-way radio shuttles, with a total of 2,124 cargo spaces.

The system does not have high requirements on warehouse height, area and rules, and has a modular design with good scalability, and the number of shuttles can be increased according to different efficiency requirements; It can realize 24-hour fully automated batch pallet operation, which is suitable for both low-flow and high-density storage in the ceramic industry and high-flow, high-density storage.

Four-way multi shuttle system

5 intensive warehouses use a four-way multi shuttle intensive warehouse system, each intensive warehouse has 4 layers, 2 mother roads, and 4 four-way multi shuttles; a total of 20 four-way multi shuttles, total cargo 21672 positions.

The system is suitable for the dismantling and picking scene of multi-variety small goods, and can realize fast picking of material boxes, cartons in and out of storage, and goods to person; It Improves picking efficiency, and the handling capacity of inbound and outbound warehouses is 3-4 times that of stacker crane automated warehouses. Storage space utilization can be as high as 95%.

Attic shuttle System

The attic shuttle system occupies less warehouse space, requires less space, and is more flexible in storage methods. It is suitable for small commodity storage, especially suitable for line-side temporary storage and picking in line with production lines. The system has a short deployment period and modular design, and the efficiency of a single unit can reach 80~100 boxes/h.

3. Deep cultivation and empowerment

At present, the overall development of the ceramic industry tends to develop in the direction of automation, digitization and intelligence. High-tech multi-functional ceramics, such as heat-resistant ceramics, antibacterial ceramics, environmentally friendly ceramics, aerospace ceramics, and other markets are growing rapidly.

As one of the famous porcelain centers in China, Jingdezhen has an important influence in the ceramic industry! Inform Storage has a deep relationship with Jingdezhen, and it has unique advantages in conducting research and cooperation in the ceramic industry and helping ceramic enterprises to “intelligence reform and turn digitally”!

On the one hand, Inform Storage has a diversified product structure, and has products and integrated services such as smart software, intelligent logistics robots, and high-precision racking. The business covers a wide range, with strong technical force, low cost and high efficiency; It can provide a variety of one-stop solutions for intelligent storage systems for the ceramic industry;

On the other hand, Jingdezhen’s “N+1+N” strategy of Inform Storage is continuously extending, including cooperation with Jingdezhen Art Vocational University to cultivate talent echelon; The first phase of the stacker crane production and manufacturing project in Jingdezhen factory has been put into construction, which has been basically completed. After the initial production capacity, the annual production capacity of stacker cranes will be 1,000 sets/year, and the annual production capacity of stacker cranes will be 2,000 sets/year after full production; Inform Storage will strengthen exchanges and cooperation with Jingdezhen ceramic enterprises, and make more contributions to the digital and intelligent development of the ceramic industry!

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: May-23-2022