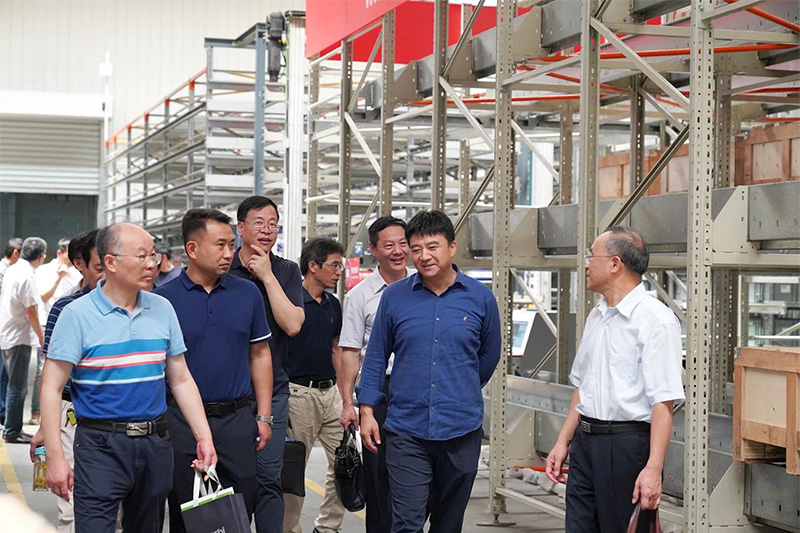

Wang Jianhua, chairman of the Jiangsu Cold Chain Society, Chen Shanling, deputy secretary, and Chen Shoujiang, executive vice chairman, accompanied by Secretary-General Chen Changwei, came to Inform Storage to conduct a work inspection. Jin Yueyue, general manager of Inform Storage, and Yin Weiguo, sales director, and other leaders warmly received.

Mr. Jin said that Inform Storage has been transforming from equipment manufacturing to service business. According to the actual needs of customers, Inform Storage can participate in investment and jointly build warehouses with customers. Inform is committed to using advanced scientific concepts and technological products that keep pace with the times to solve the problems and difficulties in the operation of the cold chain industry, and continuously contribute to the high-quality development of cold chain enterprises.

These innovative services will help traditional cold chain enterprises to transform and upgrade, realize rapid access to cold chain goods, efficient and accurate in-out and out-of-stock management and control, improve enterprise efficiency, achieve a high degree of informatization, save manpower and costs, and improve safety.

After listening to Mr. Jin’s introduction, Chairman Wang Jianhua praised the achievements of Inform Storage in the field of cold chain services, and put forward ardent expectations for the future development of Inform Storage: He said that the cold chain industry has developed rapidly in recent years. As a famous intelligent warehousing supplier, Inform Storage will have a bright future, and it should continue to work hard to further play a leading role and continue to improve its innovation capabilities.

After the meeting, under the leadership of President Jin, Chairman Wang Jianhua and others visited the Inform Storage Intelligent Equipment Laboratory. Have a detailed understanding of the company’s innovation and development process, independent and controllable product technology.

With its profound background in the field of automation and intelligence and the cold chain industry, Inform Storage has invested in a number of automated cold storage projects. Using fully automatic intelligent automated warehousing equipment, it provides intelligent cold chain warehousing and intelligent cold chain operation suitable for one-stop food logistics centers for freezing, refrigerated logistics warehousing, processing and distribution.

Hangzhou Development Zone Cold Storage Project

- 16,422 cargo spaces & 8,138 cargo spaces

- 10 lanes & 4 lanes

- 7 stacker cranes & 4 stacking cranes and inbound and outbound transportation equipment

- 4 two-way radio shuttles

- In-out warehouse conveying equipment

- 180 pallet/hour (in + out) & 156 pallet/hour (in + out)

This project is divided into three cold storages and one normal temperature storage:

The three cold storages have a total planning of 16,422 cargo spaces. With 10 lanes, 7 stacker cranes (including 2 track-change double deep stacker cranes), 4 two-way radio shuttles and in-out warehouse conveying equipment, the automatic inbound and outbound function is realized. The composite operation efficiency of the three warehouses exceeds 180 pallet/hour (in + out);

Normal temperature warehouse: The plan has a total planning of 8,138 cargo spaces. Through 4 lanes, 4 stacking cranes and inbound and outbound transportation equipment, the automatic inbound and outbound function is realized. The composite operation efficiency is 156 pallet/hour (in + out).

Shuttle mover project of a cold chain enterprise

- 998 cargo spaces & 1302 cargo spaces

- 2 sets of shuttle mover & 4 shuttle movers

- 2 sets of two-way radio shuttles & 4 two-way radio shuttles

- 2 sets of vertical conveyors of the shuttle mover & 2 pallet-type vertical conveyors

- 1 RGV

- 20 pallet/hour (in + out) & 30 pallets/hour (in + out)

Normal temperature warehouse: The total planning is 998 cargo spaces, 2 sets of shuttle mover, 2 sets of two-way radio shuttles, and 2 sets of vertical conveyors of the shuttle mover. The shuttle mover with the shuttle can change layers through the hoist, and the working efficiency is 20 pallet/hour (in + out);

Cold storage: The total planning is 1302 cargo spaces, 4 shuttle movers, 4 two-way radio shuttles, 2 pallet-type vertical conveyors, 1 RGV. There is a shuttle mover on each floor, and the goods are transported by the cargo hoist, and the operation efficiency is 30 pallets/hour (in + out);

The shuttle mover system, four-way radio shuttle system, and two-way radio shuttle system are the common high-density storage solutions in the cold chain industry, and realize the unmanned, automated, intelligent and information-based operation of the cold storage. model. Cold chain enterprises can use the smallest building area to obtain greater space utilization, and manage the cargo space through the upper software system to reduce the loss in the warehouse.

Relying on advanced technical strength and excellent system solutions in the field of intelligent warehousing, Inform Storage helps cold chain enterprises to upgrade digitally and intelligently in warehousing and logistics. In recent years, it has cooperated with many well-known cold chain enterprises in projects, and has accumulated profound experience for deep cultivation of cold chain industry warehousing development and subject research.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Jun-28-2022