Kyocera Group was founded in 1959 by Kazuo Inamori, one of the "Four Saints of Business" in Japan. At the beginning of its establishment, it mainly engaged in ceramic products and high-tech products. In 2002, after continuous expansion, Kyocera Group became one of the Fortune 500 companies, with global business areas covering raw materials, parts, equipment, machinery, as well as services, networks, and other fields. In 2019, Kyocera Group plans to build a battery factory in Osaka, western Japan, targeting the solar + energy storage market.

It is understood that Kyocera Group has high expectations for this project and plans to support Kyocera's energy storage battery business development in the next 5 years after the project is completed. ROBOTECH designed and built a automated warehouse system for it, achieving automation, digitization, and intelligent management of the entire production and storage process, helping to solve pain points such as high cost, low efficiency, multiple processes, and complex material management, reducing costs and increasing efficiency, and achieving efficient connection and collaboration between production lines and equipment.

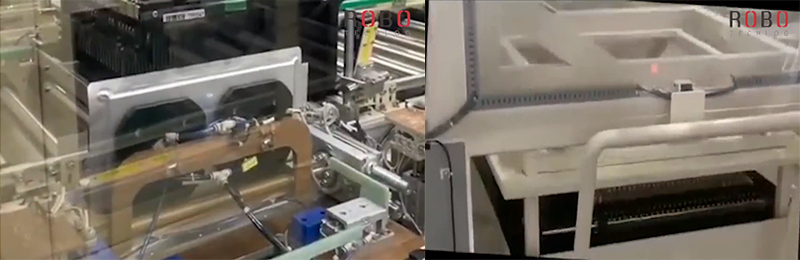

In order to improve the utilization rate of battery factory space, ROBOTECH has fully utilized more than 4m of vertical space and created a automated warehouse with two storage areas: battery charging and discharging area and battery room temperature aging area based on product quality characteristics, including two sets of stacker crane systems.

- Charging and discharging zone

- A set of stacker crane system

- 5000 cargo spaces

1. Charging and discharging zone

A set of stacker crane system has been planned in the charging and discharging regional planning to realize safe and energy-efficient storage in more than 5000 cargo spaces. In response to the high safety requirements of this project, the ROBOTECH stacker crane system is equipped with infrared thermal imagers and monitoring devices, which can detect abnormalities in a timely manner and ensure the safe operation of the entire process. And the signal is interlocked with each charging and discharging device through the optical transmission device (8bit). When the stacker crane is carrying out the "unloading" or "forking" task, a task request is sent through optical communication at the corresponding charging device location. Action can be taken only after the charging device OK signal is approved.

- Normal temperature aging zone

- One set of stacker crane system

- 400 storage locations

- Maximum load of 100KG

2. Normal temperature aging zone

One set of stacker crane system is planned for the normal temperature aging regional planning, including more than 400 storage locations, which is mainly used for temporary storage of batteries in the normal temperature aging process, with a maximum load of 100KG.

Due to the extreme sensitivity of battery materials to elements such as lead, zinc, and copper, in order to avoid metal foreign objects and dust affecting the stability of the product, ROBOTECH further customized the project based on the selection of stacker crane equipment. The walking device adopts rubber coated wheels, steel parts undergo electrostatic spraying treatment, and aluminum parts undergo anodizing treatment to reduce the generation of metal foreign objects. And fire extinguishers and armor devices have been installed for the stacker crane to meet the factory's requirements for high temperature resistance, dust-free, fire and explosion prevention.

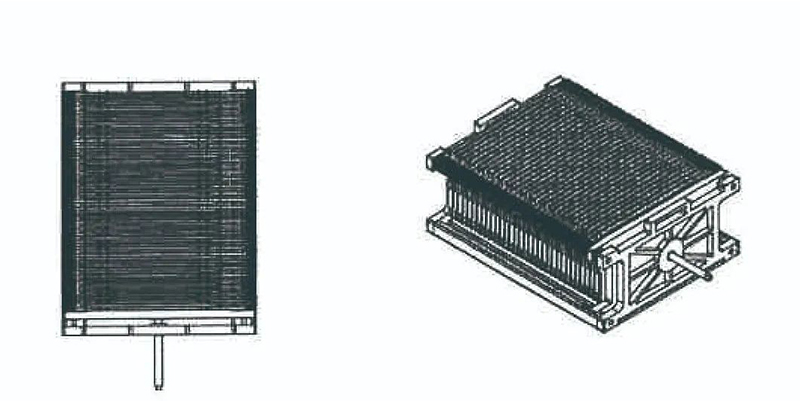

It is worth mentioning that in the production process of batteries, in order to make their performance more stable, they need to be placed in a device with compression function for room temperature rest after being formed and subjected to high temperature rest. Therefore, ROBOTECH directly uses battery pressure trays as storage carriers for storage. This type of battery pressure tray has advantages that existing technologies do not have, such as simple structure, convenient implementation, high production efficiency, small space occupation, low implementation cost, and easy implementation of automated production. In the charging and discharging storage area, adjust the pressure tray to a compressed state; In the room temperature aging storage area, adjust the pressure tray to the loose state.

Tray specification diagram: L865 * W540 * H290mm (loose state)

Tray specification diagram: L737 * W540 * H290mm (compressed state)

Tray specification diagram: L737 * W540 * H290mm (compressed state)

The completion of the project meets the efficient, safe and reliable logistics service needs of Kyocera Group in the energy storage battery business sector. With the support of the ROBOTECH intelligent warehousing system, it can greatly ensure the yield rate of battery storage. Accelerated the automation, intelligence, and sustainable development of Kyocera Group in the new energy market.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8625 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Apr-21-2023