When the earthquake occurs, the logistics storage center in the disaster area will inevitably be affected. Some can operate after the earthquake, and some logistics equipment is seriously damaged by the earthquake. How to ensure that the logistics center has a certain seismic capacity and reduce losses caused by design and manufacturing loopholes has become the focus of the logistics warehousing industry.

It is understood that the current earthquake resistance of the logistics warehousing center mainly focuses on how the civil buildings of the warehouse are earthquake resistant, how the design of the automated warehouse is earthquake resistant, and how the high-rise rackings and stacker cranes in the warehouse are earthquake resistant.

1. Earthquake resistance of civil buildings

According to the seismic fortification intensity of buildings, buildings in China are mainly divided into four categories: A, B, C and D. According to the traditional view, the single storey warehouse is recognized as Class D building. However, due to the rapid development of the logistics industry in recent years, there have been many high-rise automated warehouses with important functions, which are several times higher than traditional warehouses. In fact, such storage centers can no longer be regarded as Class D buildings, let alone should not be earthquake resistant according to the requirements of Class D buildings.

Seismic fortification is usually achieved through the following links: determining seismic fortification requirements, that is, determining the ability of buildings to resist earthquake disasters. For seismic design, seismic measures such as foundation and structure shall be taken to meet the seismic fortification requirements. The anti-seismic construction shall be carried out in strict accordance with the anti-seismic design to ensure the building quality. For seismic management, buildings in use shall not change their internal structures at will.

2. Earthquake resistance of warehouse

Generally, the embedded channel steel can be used for the ground embedment of the automated warehouse, that is, during the embedment, each row of embedded bolts connected to the rack column are connected with a whole channel steel, and then the channel steel is connected with angle steel, so that the whole ground, the rack and the building steel structure, the color steel plate form a whole, and its seismic capacity is greatly enhanced.

In addition to the foundation pressure under the static load of the stacker crane and the racking, the increase of other loads under the seismic condition, the horizontal pressure during the earthquake and the upward tension of the stacker crane should also be considered. These values will be multiplied compared with the static pressure.

3. Seismic resistance of high-rise equipment

In addition to the anti-seismic design of civil buildings and systems, the most important thing is to consider how high-rise equipment such as rackings and stacker cranes have anti-seismic capacity.

The seismic capacity of the racking mainly depends on its rigidity and flexibility. The rigidity mainly depends on the strength of the selected racking production materials and the thickness of the shelf. The importance of flexibility is equal to that of stiffness, which mainly depends on the design of the racking structure.

For the stacker crane operating at a high position, its auxiliary equipment, namely, the sky rail and the ground rail, shall be prevented from twisting, deformation and even fracture in case of earthquake.

Finally, in the use and management of the warehouse, the warehouse must be operated according to the maintenance manual of the warehouse, and the necessary maintenance must be carried out according to the specified time.

Inform automation equipment:

Four-way shuttle

Advantages:

- It is the only way to drive along the longitudinal or transverse track in any direction on the crossing track;

- The two-way driving makes the system configuration more standardized;

Core functions:

- The four-way shuttle is mainly used for the automatic handling and transportation of pallet goods in the warehouse;

- Automatic access to goods, automatic lane change and floor change, intelligent leveling, and direct access to any location of the warehouse;

- It can be driven on the rack track or on the ground without being limited by the site, road and slope, fully reflecting its automation and flexibility;

- It is an intelligent handling equipment integrating automatic handling, unmanned guidance, intelligent control and other functions;

The four-way shuttle is divided into four-way radio shuttle and four-way multi shuttle.

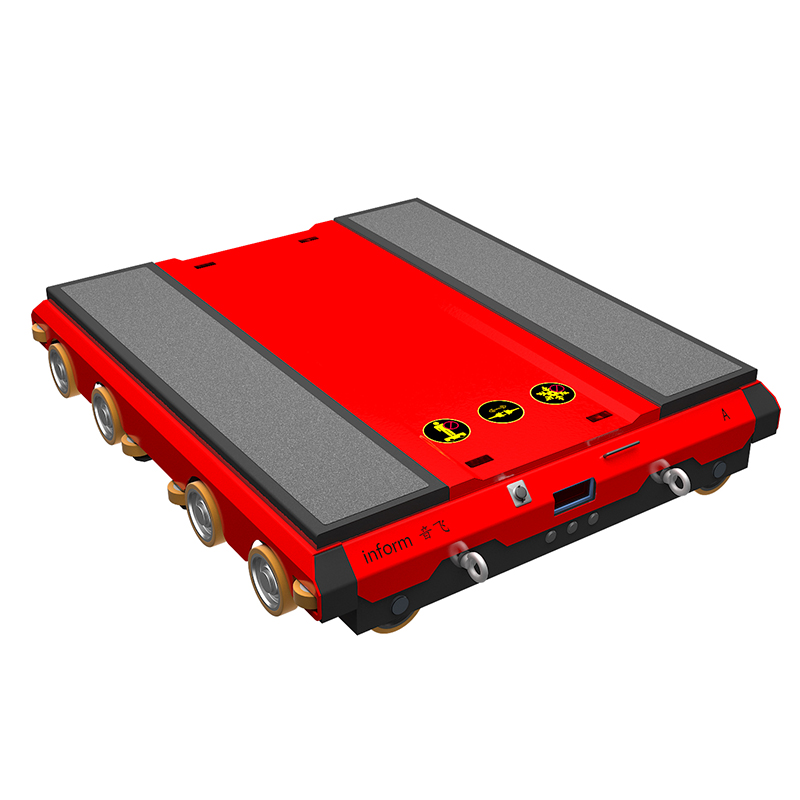

Four way radio shuttle

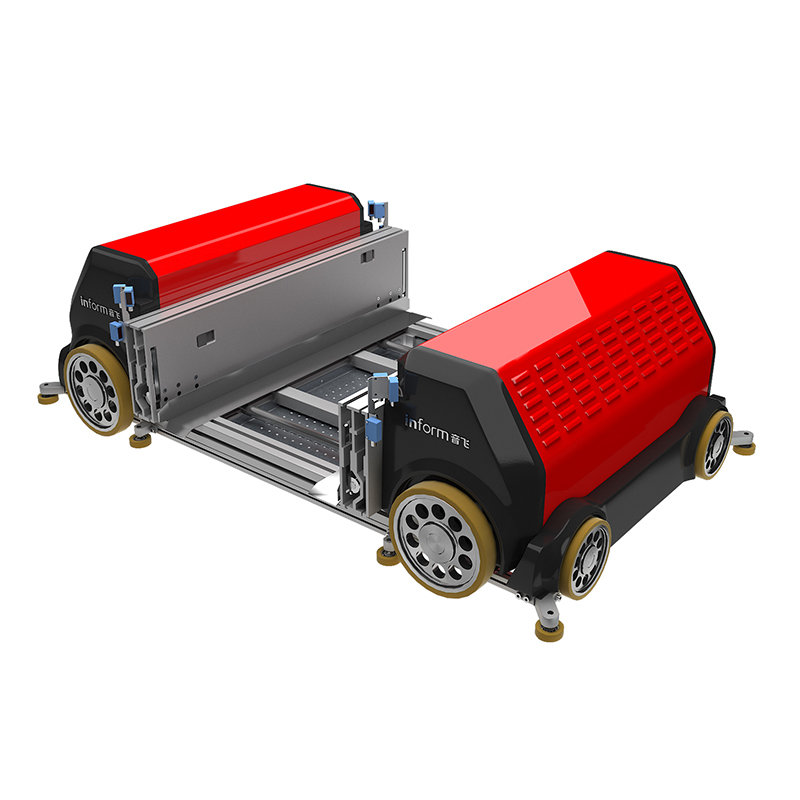

Four way multi shuttle

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Jan-06-2023