The COVID-19 has been raging for many years, and the research and development of vaccines and specific therapeutic drugs has become a topic of global attention. According to the People’s Daily, the blood of recovered patients with the COVID-19 contains a large amount of antibodies, which can effectively resist the virus; This is undoubtedly another major breakthrough in the treatment of new coronary pneumonia since the outbreak of the epidemic.

Due to the particularity of blood, the temperature needs to be strictly controlled between 2°C~8°C, while long-term storage of plasma requires a storage environment of -20°C~-70°C. So, how to realize automatic & unmanned access at low temperature and ensure the timeliness and safety of transportation?

HUALAN BIO Cold storage automation goal

Hualan Bio is a high-tech enterprise engaged in the development and production of vaccine products and genetically engineered drugs. The main business includes blood products, vaccines, and monoclonal antibodies. Among them, the plasma processing capacity ranks among the top in China and even in Asia, and it is the enterprise with the most variety and complete specifications of blood products in China. Caring for life, people-oriented, in order to ensure the safety and effectiveness of each product, Hualan Bio has strict requirements on storage and handling.

Customer problems and expectations

• Provides high-density storage for low-turnover inventory

• Automatically access items

• Eliminate item access confusion and inefficiencies

• Create a more comfortable working environment for workers

• Minimize labor

• Timeliness and safety of transportation

Hualan Bio and ROBOTECH to implement automated warehouse

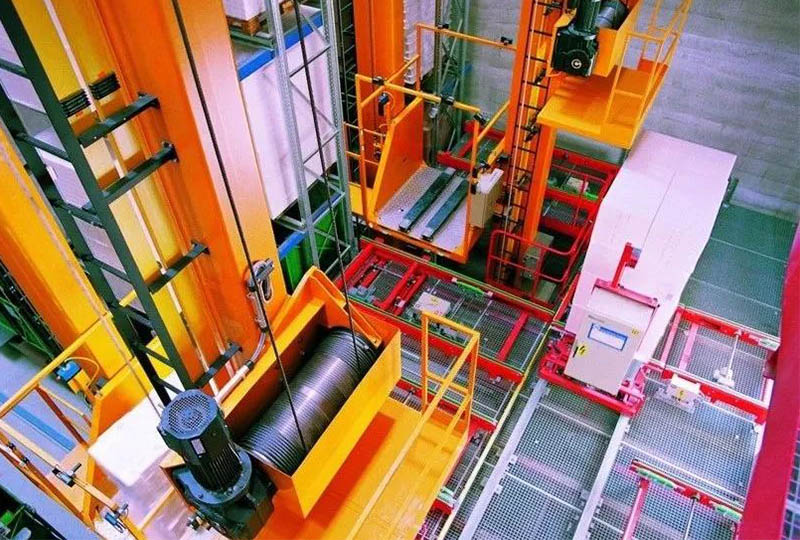

Hualan Bio’s product development is based on biotechnology, which requires very high temperature. Based on this feature, ROBOTECH has built a set of intelligent cold storage system solutions for Hualan Bio that integrates plasma storage, sampling, sorting, production and delivery, and transportation.

The cold storage system automatically enters and exits the corresponding batches and different SKU plasma according to the production demand order, which greatly reduces the workload and provides strong support for the staff. In addition, products in and out of the warehouse follow the FIFO principle. To ensure that the plasma can be cooled rapidly when entering the warehouse, the residence time of the product in the low temperature buffer area or the normal temperature area should be reduced, and the entry and exit time should be controlled within 1 hour.

ROBOTECH also paid great attention to the design and material selection of the pallet stacker crane in this project. The selected welding parts, steel and grease are all suitable materials for low temperature. In order to ensure the high reliability and high-speed operation of the equipment in the low temperature environment, the Panther series models with a maximum operating speed of up to 240m/min and an acceleration of up to 1m/s2 are selected. It can achieve continuous high throughput while meeting the storage environment of -30℃ and 2-8℃.

Project effect

• Advanced logistics system, seamlessly integrated with the original system

• Highly automated for maximum efficiency

• Significantly improved material handling speed

• Reliable, uninterrupted cold chain logistics

• Reliable quality management, tracking and tracing, in line with GMP standards

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Jul-06-2022