On July 12, the 2022 7th Global Power Li-ion Battery Anode Material Summit hosted by Wangcai New Media was held in Chengdu. With its rich experience and innovative technology in the lithium battery industry, ROBOTECH was invited to attend this summit. And gathered together with many lithium raw materials, cathode material industry experts and corporate executives. From the lithium battery raw materials industry chain market, market, technology and other aspects to communicate and discuss the future market trend and cutting-edge technology development.

In the context of dual carbon, with the upgrading of lithium battery cathode material technology and the continuous expansion of the scale of the industrial chain, the mismatch between supply and demand of various raw materials in the industrial chain has gradually become prominent. It has become an inevitable trend for the large-scale production of lithium battery industry to realize the simplification of process flow, automation of production lines, and flexible upgrade of logistics with intelligent manufacturing.

1. Problems

• The impact of metals and dust on products: Lithium battery cathode materials are extremely sensitive to elements such as lead, zinc, and copper. Factors such as dust and metals can affect product consistency. The traditional material flow and access mainly rely on manual contact, resulting in high material scrapping rate.

• Information barriers for each process: There are many production processes of cathode materials for lithium batteries, resulting in a large number of cached materials, requiring manual periodic inventory, and no real-time inventory data; and a large amount of data generated by different devices is difficult to coordinate, facing information islanding and precise docking Insufficient degree and so on.

• Operational safety: The traditional manual line-side logistics has high environmental risks, and the safety of human-

machine mixed operation is high.

2. ROBOTECH lithium battery raw material logistics upgrade

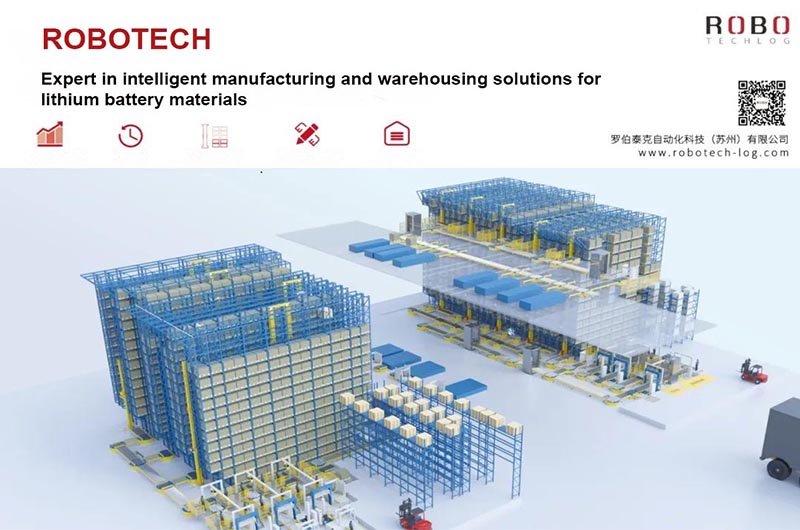

ROBOTECH has a lot of experience in warehousing upgrade cases in the field of positive and negative raw materials for lithium batteries. It can perform flexible design according to the process rhythm and needs, and provide customized intelligent warehousing equipment systems and intelligent scheduling system solutions. Complete the whole process of warehousing automation from automatic storage of materials, picking and feeding of production lines, transportation and packaging, and delivery of finished products.

The combination of hardware and software of ROBOTECH can flexibly configure various modular systems such as vertical warehouse system, conveying system, air shower system, pallet changing system, AGV system and packaging system according to the needs of the scene. The intelligent management of warehousing is realized by dispatching various hardware system modules through WCS/WMS intelligent factory logistics software, which can meet most of the needs of lithium battery warehousing and distribution links.

3. ROBOTECH stacker crane innovative technology.

The raw materials of lithium battery cathode materials are mainly LFP (lithium iron phosphate) and high nickel ternary. The raw materials and finished products are easy to expand, have large dust, and have high requirements for metal foreign objects. Due to the special type of goods, production equipment is required to control foreign metal objects, and the goods may expand and collapse when stored for a long time. Therefore, compared with conventional equipment design requirements, the requirements for safety, reliability and compatibility are higher.

Logistics robots are the backbone of intelligent and unmanned intelligent warehousing scenarios, and ROBOTECH has been focusing on the research and development of intelligent logistics equipment and management systems for more than 30 years, and has a rich product line. For the flammable and explosive characteristics and production process requirements of the lithium battery industry. On the basis of the mature models of the original Zebra series of light-duty box-type stacker cranes, the armored device has been developed, which has the functions of automatic sealing of the loading platform, automatic fire extinguishing, dust and smoke prevention and so on. Based on the attributes of the lithium battery industry, the equipment level meets the cleanliness level of one million, strictly controls foreign metal objects, and protects and isolates moving parts to ensure safe and reliable operation of equipment and clean production.

Intelligent warehousing and logistics has become the third profit source for enterprises. As a leader in intelligent logistics solutions, ROBOTECH is committed to providing flexible, accurate and efficient intelligent logistics services, creating value for enterprises, shaping competitiveness, and promoting the extreme manufacturing of lithium battery industry.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Jul-15-2022