1. About Weichai

Weichai was founded in 1946, with a global workforce of 90000 people and a revenue of over 300 billion yuan in 2020. It ranks 83rd among the top 500 Chinese enterprises, 23rd among the top 500 Chinese manufacturing companies, and 2nd among the top 100 Chinese mechanical industry enterprises. Starting from 1946, in 77 years, Weichai has developed from a local diesel engine factory into a multinational group that integrates business sectors such as power systems, commercial vehicles, agricultural equipment, engineering machinery, smart logistics, and marine transportation equipment. Its subsidiaries are located in Europe, North America, Asia, and other regions, and its products are exported to more than 110 countries and regions.

Although Weichai is located in the traditional manufacturing field, its exploration of digitization and intelligence has been at the forefront of the industry. As early as 2006, it took the lead in attempting automated warehouse for storing sand cores. In recent years, Weichai has been committed to automation and intelligent transformation and upgrading. This investment in the construction of an automated warehouse is planned by Weben Electromechanical as the overall solution, responsible for the AS/RS and related supporting systems, sorting equipment systems, sorting and conveying systems, and related services of the vertical warehouse. Among them, the three major storage areas of the sand core warehouse, plate type warehouse, and tooling warehouse are designed and delivered by ROBOTECH as the automatic storage system of the automated warehouse.

2. Outstanding strength and unique craftsmanship

- 5 sets of track tunnel stacker crane systems

- 2 sets of sand core warehouses

- 1288 storage spaces

- 1 set of plate type warehouses

- 256 storage spaces

- 2 sets of tooling warehouses

- 1040 storage spaces

The automated warehouse adopts a total of 5 sets of track tunnel stacker crane systems, with 2 sets of sand core warehouses containing 1288 storage spaces, 1 set of plate type warehouses containing 256 storage spaces, and 2 sets of tooling warehouses containing 1040 storage spaces.

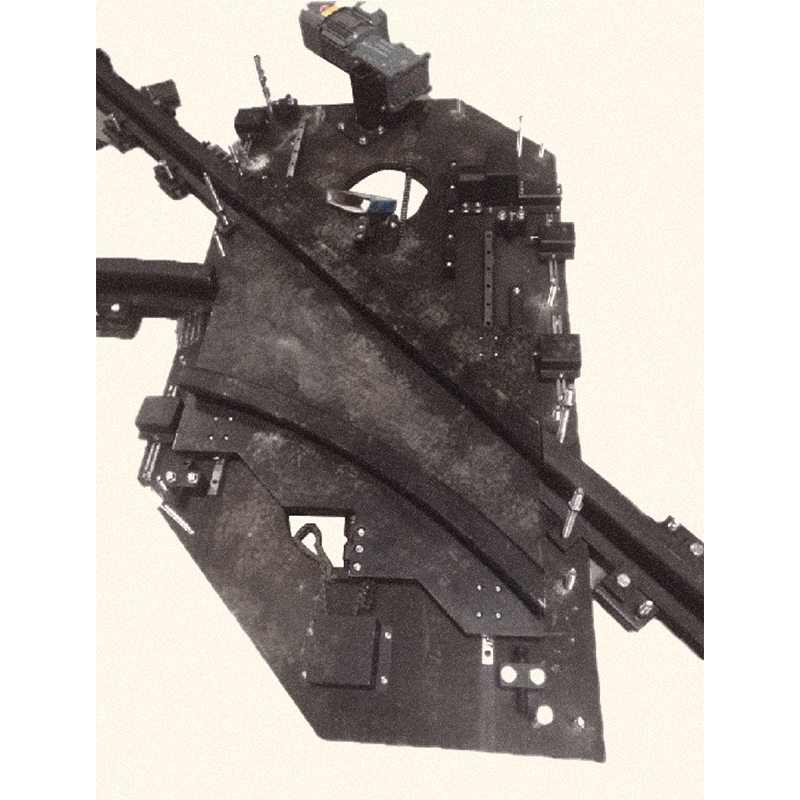

Among them, the size of the goods in the tooling warehouse is relatively large and the load is heavy. ROBOTECH has designed two “bull” stacker cranes that can carry 7000kg of materials. The specifications of the goods handled are 1600mm in length, 1600mm in width, and 1770mm in height. The total height of the warehouse area is about 12m, and the warehouse length is 114m. The Bull model is stronger, and more reliable. The main beam is made of steel rectangular tubes, which have sufficient compression and torsion resistance. Reinforced ribs are welded inside the column to increase torsion and bending strength to meet the use of heavy-duty goods.

Track changer

Based on the actual operation of each reservoir area, ROBOTECH has innovatively designed a “transition mechanism“, which has the following two advantages:

1) Cost saving: In practical applications, some warehouses are not frequently used, and only one stacker crane is needed for two lanes, which can be achieved by turning.

2) High reliability: the turning stacker crane has continuous top rails, ground rails, and power supply system sliding contact lines throughout the entire operation process, without any breakpoints in the middle, reducing the wear of sliding contact line carbon brushes and guide rails, and improving the reliability of the power supply system.

Weichai has established an advanced automated warehouse to automate the entire process of material flow from procurement, warehousing, and picking to pulling out of the warehouse. It adopts big data analysis technology to achieve dynamic visualization of warehouse data, optimize warehouse layout, sorting rules, personnel configuration, etc., improve delivery execution efficiency, achieve 100% accuracy, and form an efficient intelligent warehousing and distribution system, Effectively supporting large-scale customization and flexible production for enterprises.

ROBOTECH’s highly flexible, high-tech, and innovative automated warehouse access solutions have helped Weichai achieve high automation, intelligence, and efficiency, creating a safe, green, and humanized atmosphere, ensuring the efficient operation of production lines, meeting the efficient and reliable logistics service needs of enterprises, and increasing consumer demand, becoming another benchmark for Weichai’s intelligent transformation.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926 / +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: [email protected]

Post time: Sep-26-2023