Hot-selling High-Density Storage – Shuttle Racking – INFORM

Hot-selling High-Density Storage – Shuttle Racking – INFORM Detail:

Racking Components

Product Analysis

| Racking type: | Shuttle racking | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 500-1500kg/pallet |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 75mm | Place of origin | Nanjing, China |

| Application: | Suit for industries like food, chemical, tobacco, beverage, which are with high volume but few types of cargoes(SKU) It’s very popular in cold storage, also the correct choice for the enterprises with limited storage space. | ||

① Safe for operation

Shuttle racking system is often compared to drive in racking system, because they are similar racking structure and storage density. However, shuttle racking provides significant advantages. Compared with drive in racking, the structure of shuttle racking is more stable. Operator and forklift don’t need to go inside of racking for pallet loading and unloading, so it’s safer for operation, and brings less damage to racking unit.

② High working efficiency

Forklift carries radio shuttle cart to the rack end, and then it can start to work. The pallet moving is operated by radio shuttle cart instead of forklift operation, so it enjoys high working efficiency.

Cargoes access can be first in first out(FIFO), or first in last out(FILO), reducing waiting time.

③ High space utilization

Shuttle racking is an excellent solution of maximized utilization of warehouse space, because of its deep-lane design and easy access to pallets from the rack ends. It saves warehouse space by eliminating aisles, so pallet storage positions are increased accordingly.

About warehouse space utilization rate, heavy-duty racking is 30%-35%, drive in racking is 60%-70%, while shuttle racking can be up to 80%-85%.

④ Once invested, lifelong benefit

The typical advantage of shuttle racking is the semi-automated storage mode. Compared with other automated storage system, shuttle racking is more comprehensive, and cost-effective. One the basis of same staff numbers, shuttle racking is able to raise working efficiency during actual operation.

Project cases

Chemical Industry

Beverage Industry

Tobacco Industry

Why choose us?

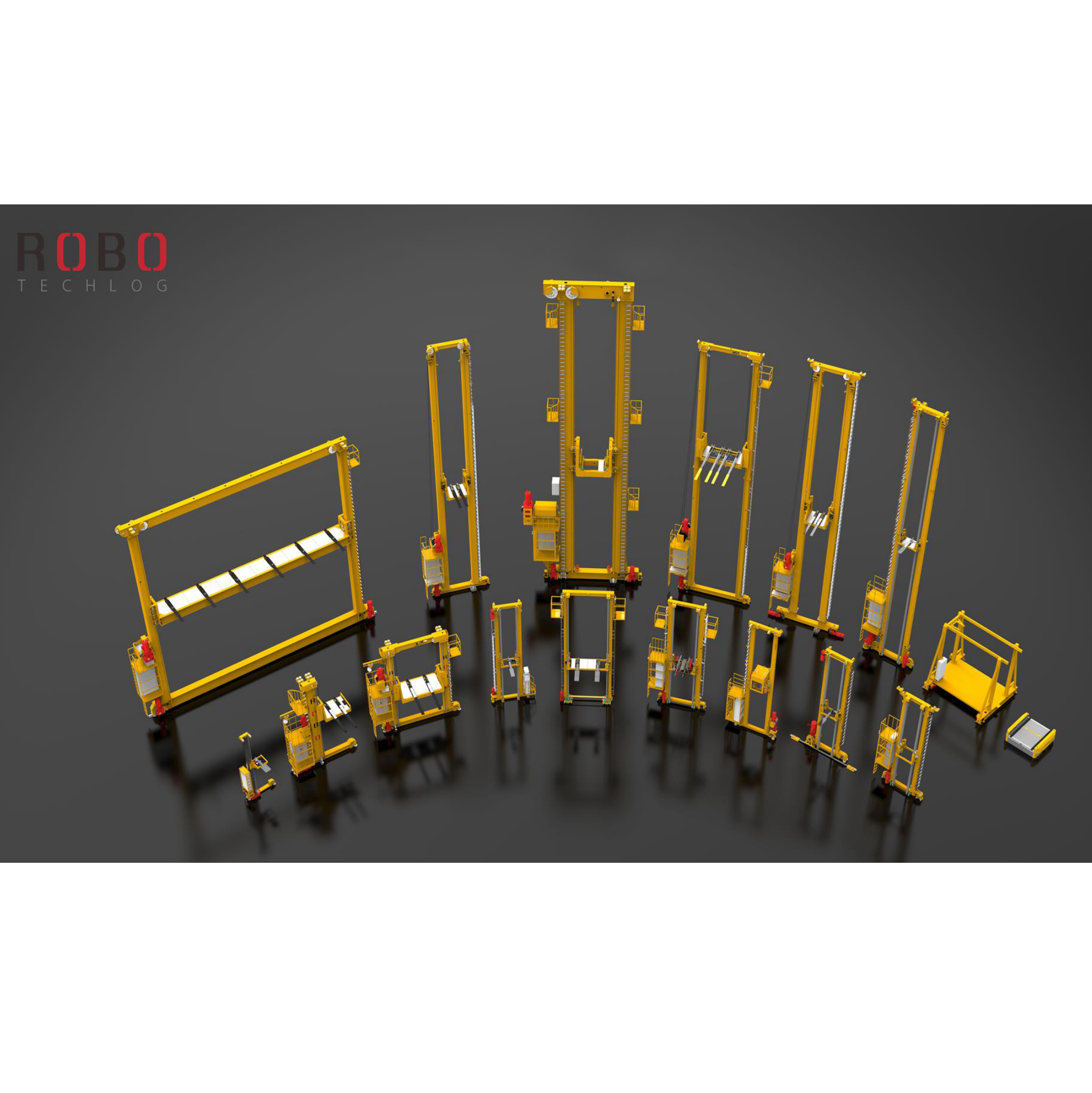

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Hot-selling High-Density Storage – Shuttle Racking – INFORM, The product will supply to all over the world, such as: Angola , Serbia , Brasilia , We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.