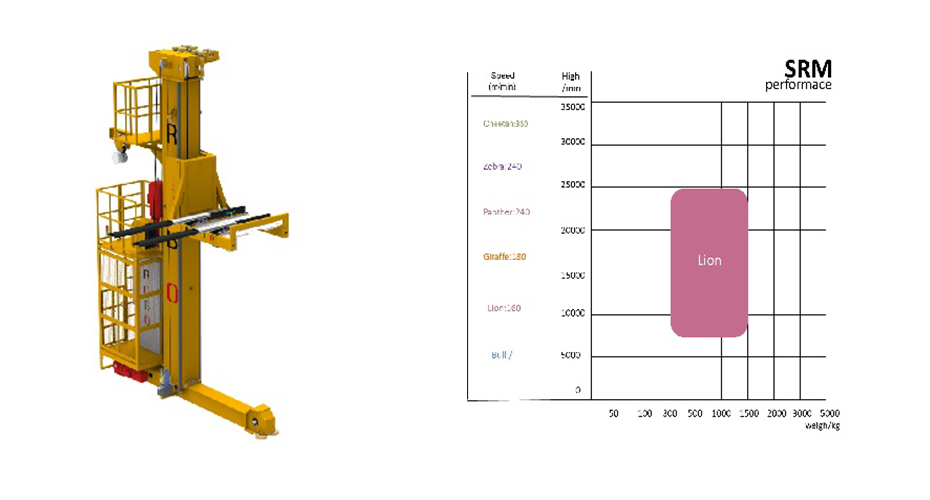

High Quality Automated Racking System – Lion Series Stacker Crane – INFORM

High Quality Automated Racking System – Lion Series Stacker Crane – INFORM Detail:

Product Details

Product Analysis:

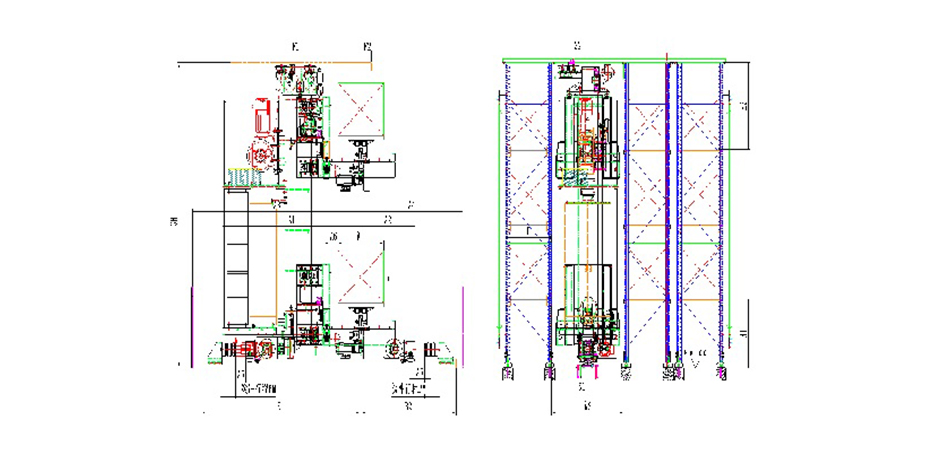

| Name | Code | Standard value(mm)(detailed data is determined according to the project situation) |

| Cargo width | W | 400 ≤W ≤2000 |

| Cargo depth | D | 500 ≤D ≤2000 |

| Cargo height | H | 100 ≤H ≤2000 |

| Total height | GH | 3000<GH ≤24000 |

| Top ground rail end length | F1、F2 | Confirm according to the specific plan |

| Outer width ofstacker crane | A1、A2 | Confirm according to the specific plan |

| Stacker crane distance from the end | A3、A4 | Confirm according to the specific plan |

| Buffer safetydistance | A5 | A5 ≥300 (polyurethane), A5 ≥ 100 (hydraulic buffer) |

| Buffer stroke | PM | PM ≥ 150 (polyurethane), specific calculation (hydraulic buffer) |

| Cargo platformsafety distance | A6 | ≥ 165 |

| Ground rail endlength | B1、B2 | Confirm according to the specific plan |

| Stacker crane wheel base | M | M=W+1300(W≥700), M=2600(W<700) |

| Ground rail offset | S1 | Confirm according to the specific plan |

| Top rail offset | S2 | Confirm according to the specific plan |

| Pickup itinerary | S3 | ≤3000 |

| Bumper width | W1 | - |

| Aisle width | W2 | D+200(D≥1300), 1500(D<1300) |

| First floor height | H1 | Single deep H1 ≥650, double deep H1 ≥750 |

| Top level height | H2 | H2 ≥H+1450(H≥900),H2 ≥2100(H<900) |

Advantages:

Lion series, very strong and powerful single-column stacker crane, up to 46m in height. It can carry pallets weighing up to 1500kg, with a speed of 200m/min and an acceleration of 0.6m/s2.

• Height up to 25 meters.

• Shorter end distance for flexible installation.

• Variable frequency drive motor (IE2), running smoothly.

• Fork units can be customized to handle a variety of loads.

• The end size can be saved by about 500mm.

• The minimum height of the first floor: 650mm (single deep), 750mm (double deep)

Applicable Industry: cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

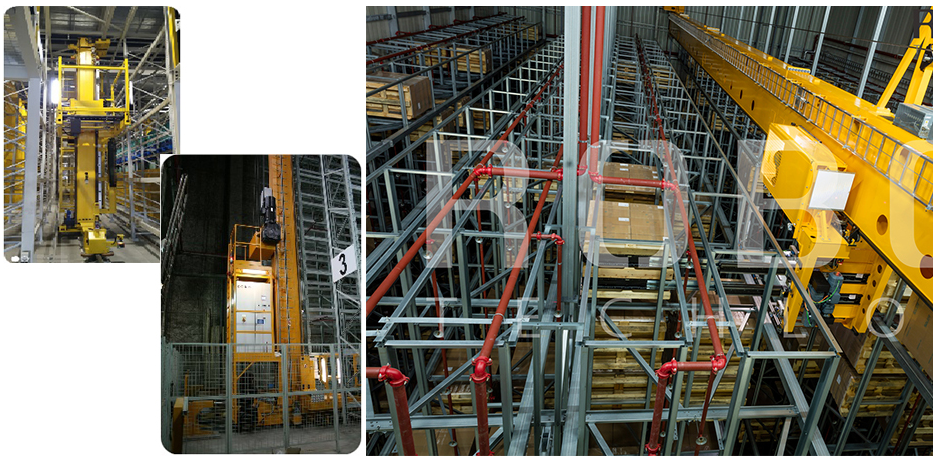

Project case:

| Model Name |

SMHS-P1-1500-08 | ||||

| Bracket Shelf | Standard Shelf | ||||

| Single deep | Double deep | Single deep | Double deep | ||

| Maximum height limit GH | 8m | ||||

| Maximum load limit | 1500kg | ||||

| Walking speed max | 160m/min | ||||

| Walking acceleration | 0.5m/s2 | ||||

| Lifting speed(m/min) | Fully loaded | 20 | 20 | 20 | 20 |

| No load | 55 | 55 | 55 | 55 | |

| Lifting acceleration | 0.5m/s2 | ||||

| Fork speed(m/min) | Fully loaded | 30 | 30 | 30 | 30 |

| No load | 60 | 60 | 60 | 60 | |

| Fork acceleration | 0.5m/s2 | ||||

| Horizontal positioning accuracy | ± 3mm | ||||

| Lifting positioning accuracy | ± 3mm | ||||

| Fork positioning accuracy | ± 3mm | ||||

| Stacker crane net weight | About 6000kg | About 6500kg | About 6000kg | About 6500kg | |

| Load depth limit D | 1000~1300(inclusive) | 1000~1300(inclusive) | 1000~1300(inclusive) | 1000~1300(inclusive) | |

| Load width limit W | W ≤ 1300 (inclusive) | ||||

| Motor specification and parameters | Level | AC;11kw(single deep)/11kw(double deep);3 ψ;380V | |||

| Rise | AC;11kw;3 ψ ;380V | ||||

| Fork | AC;0.75kw; 3ψ;4P;380V |

AC;2*3.3kw; 3ψ;4P;380V |

AC;0.75kw ; 3ψ ;4P;380 V |

AC;2*3.3kw; 3ψ ;4P;380V |

|

| Power supply | Busbar(5P; including grounding) | ||||

| Power supply specifications |

3 ψ ;380V±10%;50Hz | ||||

| Power supply capacity | Single deep is about 44kw;double deep is about 52kw | ||||

| Top ground rail specifications | Anglesteel 100*100*10mm(The installation distance of the ceiling rail is not more than 1300mm) | ||||

| Top rail offset S2 | -300mm | ||||

| Ground rail specifications | 30kg/m | ||||

| Ground rail offset S1 | 0mm | ||||

| Operating temperature | -5 ℃~40℃ | ||||

| Operating humidity | Below 85%, no condensation | ||||

| Safety devices | Prevent walking derailment: laser sensor, limit switch, hydraulic buffer Prevent lifts from topping or bottoming: laser sensors, limit switches, buffers Emergency stop function: emergency stop button EMS Safety brake system: electromagnetic brake system with monitoring function Broken rope (chain), loose rope (chain) detection: sensor, clamping mechanism Cargo position detection function, fork center inspection sensor, fork torque limit protection Cargo anti-fall device: cargo shape detection sensor Ladder, safety rope or safety cage |

||||

Product detail pictures:

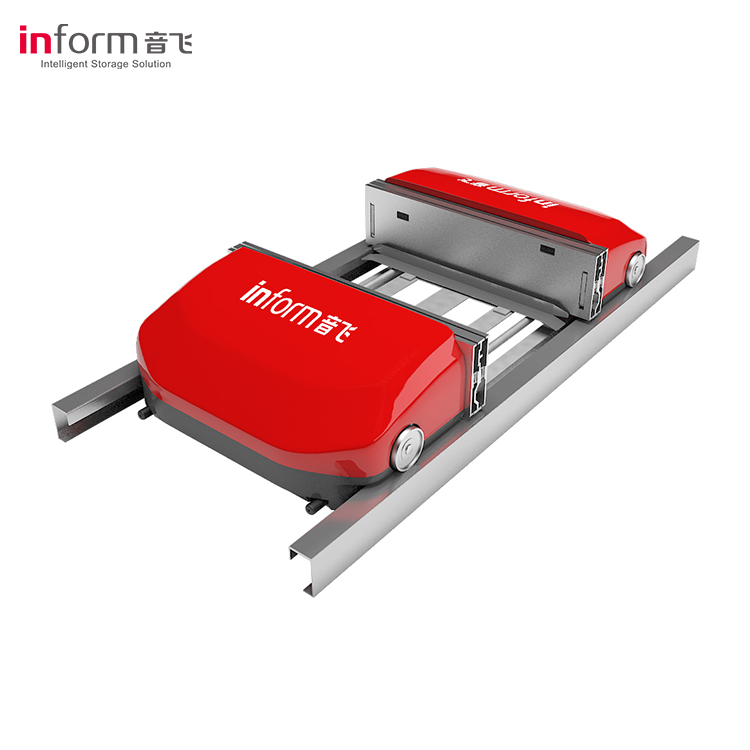

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for High Quality Automated Racking System – Lion Series Stacker Crane – INFORM, The product will supply to all over the world, such as: Argentina, Roman, Boston, To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our merchandise list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're about to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.