High definition Dense Storage Racking - Carton Flow Racking – INFORM

High definition Dense Storage Racking - Carton Flow Racking – INFORM Detail:

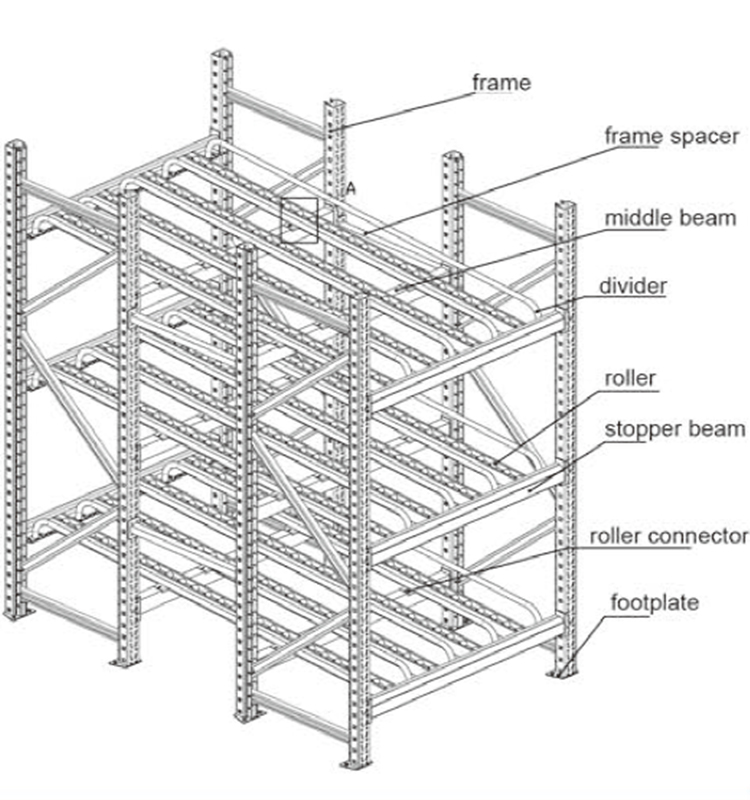

Racking Components

Product Analysis

| Racking type: | Carton flow racking | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 100-1000kg/level |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 50mm | Place of origin | Nanjing, China |

| Application: | supermarket, pharmaceutical, chemical and electronics industries | ||

① Working Principle

The working principle of carton flow racking is similar to gravity racking, the main difference is that gravity racking is for pallet moving, while carton flow racking is for carton or box/bin moving. Cartons are flowed from one side, and retrieved from the other.

◆Accessory: With a picking station in front of racking, it’s easier for operator to dispense carton or box/bin.

◆Accessory: With round tube divider between roller, each box at horizontal direction can be divided to avoid collision. It’s quite necessary for battery storage.

② FIFO racking type

This system uses a combination of rails and Wheels. The rails are built on a slight incline, higher on the side that is flowed, so that the cartons move forward when they are loaded into the system. Cartons of identical products are loaded in one behind the other. The carton flows forward under gravity to create a strict ‘First In ,First Out’ moving rotation.

③Adaptability with other racking

Carton Flow racking can be integrated with other racking types to create more storage modes. For example, carton flow racking + selective pallet racking; carton flow racking + mezzanine.

carton flow racking + selective pallet racking

carton flow racking + mezzanine

④Advantages

Carton Flow dynamic storage system offers many advantages in the order picking process.

• Reducing walking

• Saving space by eliminating walkways

• Improving picking speeds and productivity

Project cases

Why choose us?

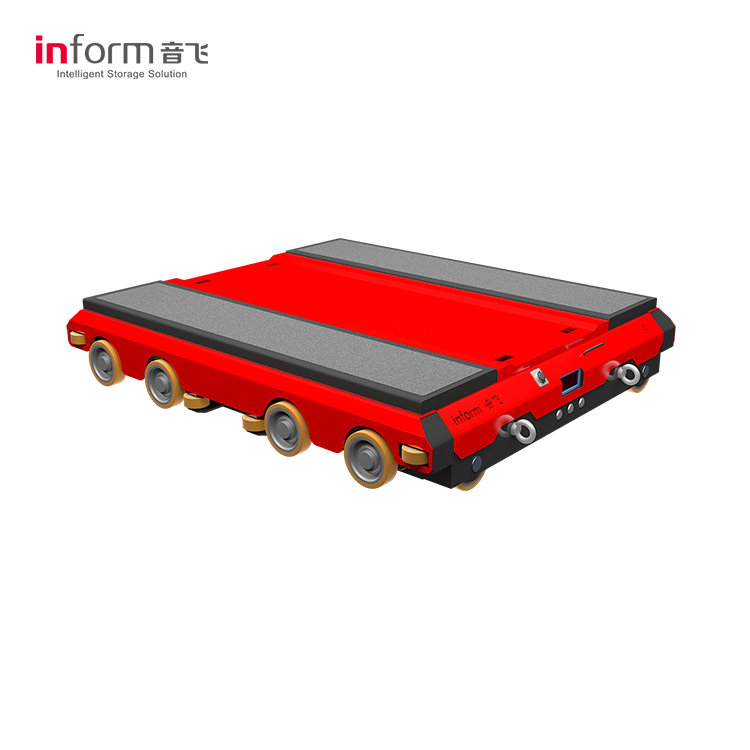

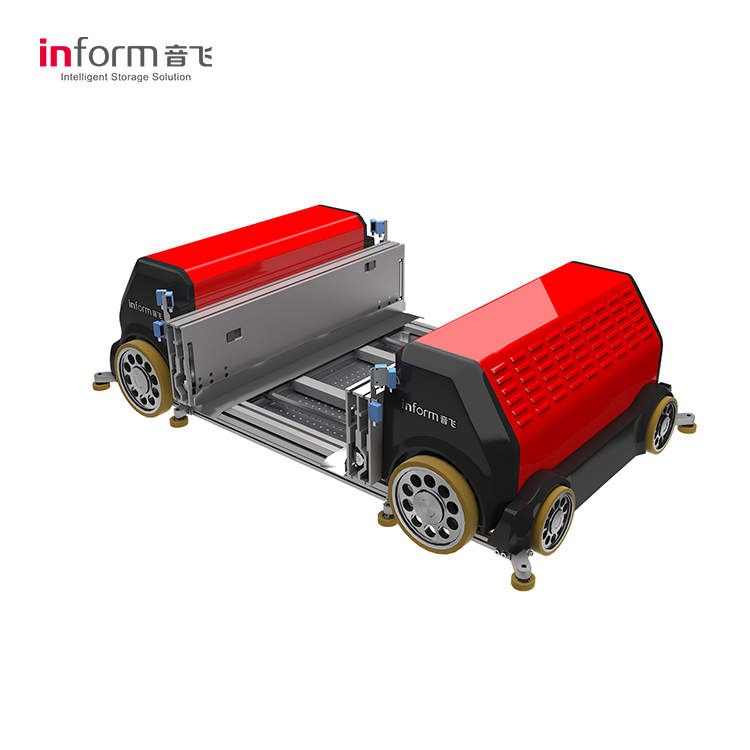

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for High definition Dense Storage Racking - Carton Flow Racking – INFORM, The product will supply to all over the world, such as: Zambia, Birmingham, Kuwait, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.