Four Way Radio Shuttle

Overview

Product Analysis

①Functions

| 1 | Manual function | Manually operate shuttle to forward, backward, jacking, putting down, transfer direction, etc. by testing software. |

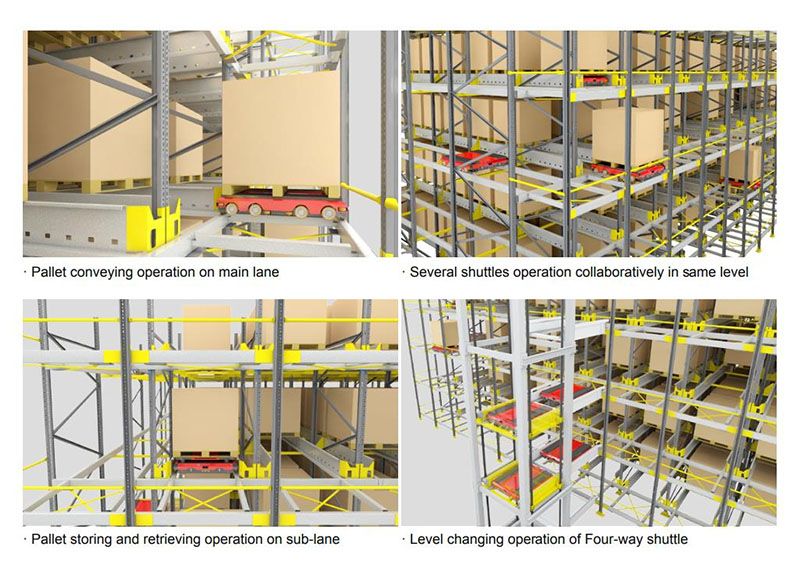

| 2 | Automatic in and out | Four-way shuttle performs inbound and outbound operation for pallets by scheduling software. |

| 3 | Automatic shifting | Four-way shuttle shifts pallets from one position to specified one in another lane by scheduling software. |

| 4 | Counting | Automatically count the number of lane’s pallet, and automatically count daily total inbound and outbound pallets. |

| 5 | Self-learning function | Automatically measure, identify data of racking and pallet, and enter parameters independently. |

| 6 | Charging online | - Multi-level power threshold control, self-judging and self-charging on line.- In particular cases, shuttle can be charged out of line emergently. |

| 7 | Alarm in low battery | When low battery, the alarm buzzes, shuttle stops after finishing current task, is not to accept operation instruction. It requests host computer to charge, and back to charging position to recharge after accepting charging order. |

| 8 | Status presentation | It possesses indicator light to show alarm, standby, work and so forth |

| 9 | Remote control | - One press to switch online and manual operation on remote control mode.- Support status monitoring and test based on mobile phone (Android) or Tablet PC (Optional, only manual mode) |

| 10 | System monitoring | Power on self test on device, monitoring system data in real time and alarm in sound and light in abnormal status. |

| 11 | Remote function | It is capable of updating and downloading program remotely (In Wi-Fi Network). |

| 12 | Heartbeat check | Communicate to host computer control system in real time by heartbeat check, monitoring online status |

| 13 | Emergency Stop | Emergency signal sent remotely when emergency, and shuttle stops instantly until emergency lifted.It is capable of guaranteeing device or goods stop safely in maximal deceleration when it executes this instruction. |

| 14 | Log record and upload | It is capable of recording operational log and uploading to host computer regularly. |

②What kind of goods are suitable for Four-way Shuttle storage system ?

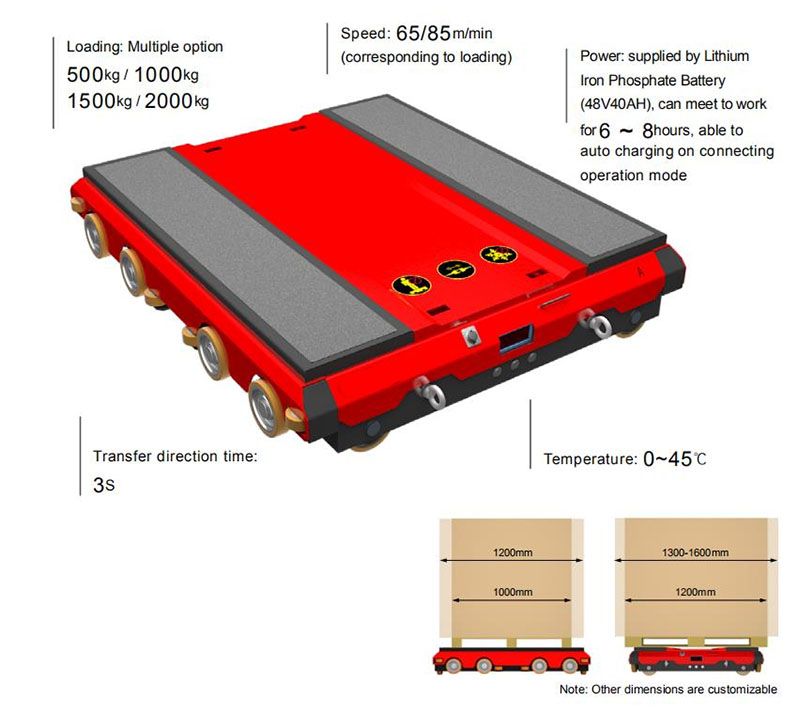

| Goods package type | Pallets |

| Goods dimension(mm) | W1200-1300xD1000-1200mm; W1400-1600xD1000-1200mm. |

| Good weight | <=2000kg |

| Operation height | <=15m |

③Design, Test , Warranty & Applicable Industry

Design

Free design could be provided with the following information.

Warehouse storage area Length____mm x Width____mm x Clear height___mm.

Warehouse’s door position for loading and unloading goods.

Pallet Length____mm x Width____mm x Height___mm x Weight_____kg.

Warehouse Temperature_____Degrees Celsius

Inbound and outbound efficiency: Quantity of pallets per hour_____.

Test

Four-way Shuttle will be tested before delivery. Engineer will test the whole system on-site or online.

Warranty

Warranty is one year. Fast response within 24 hours for overseas customer. Firstly test online and adjust ,if couldn’t repair online , engineer will go and solve the problems on site. Free spare parts will be supplied during the warranty time.

Applicable Industry

Cold chain storage (-25 degree) , freezer warehouse , E-commerce , DC center , food and beverage , chemical , Pharmaceutical industry,automotive ,lithium battery Etc.

Project cases

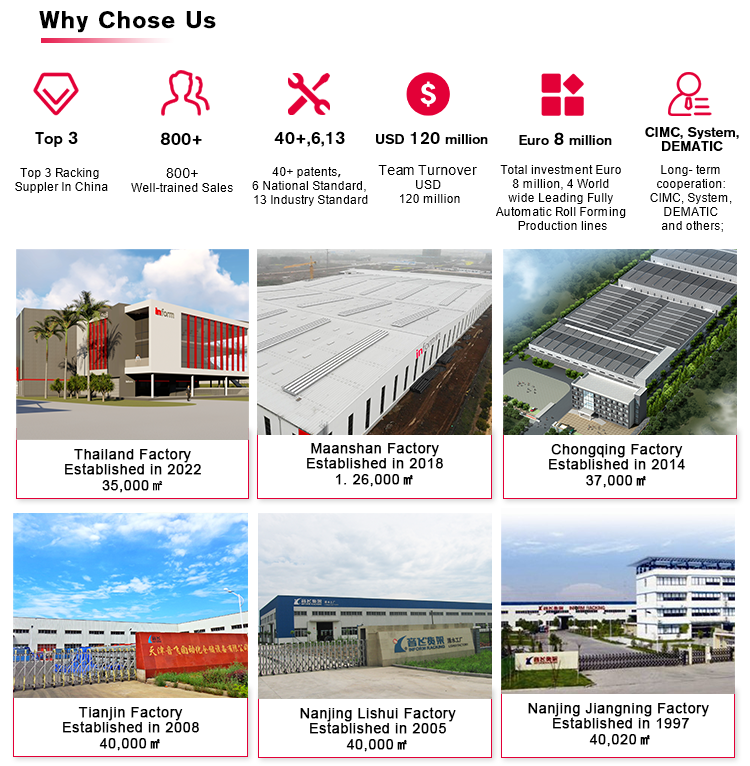

Why Choose Us

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed enterprise, specialized in the logistic storage solution field since 1997( 27 years of experience).

2. Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3. Inform owns 6 factories, with over 1500 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.