Featured

-

China Factory for Shuttle Company - Four-Way Multi Shuttle – INFORM

Racking Components Product Analysis 1 Automatic single inbound Accepting instruction from host computer, automatically conveys box on inbound buffer area to specified position. 2 Automatic single outbound Accepting instruction from host computer, conveys box on specified position to outbound end. 3 Automatic shifting Accepting instruction from host computer, conveys box from one specified position to another. 4 Charging online Multi-level power threshold control, self-jud... -

Best-Selling Galvanised Racking - AS/RS Racking – INFORM

Racking Components Product Analysis Racking type: AS/RS (Automated Storage and Retrieval System) Material: Q235/Q355 Steel Certificate CE, ISO Size: customized Loading: 1000-3000kg/pallet Surface treatment: powder coating/galvanized Color: RAL color code Pitch 75mm Place of origin Nanjing, China Application: industrial production, logistics, commodity manufacturing , military applications industries ① High space Utilization The space utilization of AS/RS is 2-5 tim... -

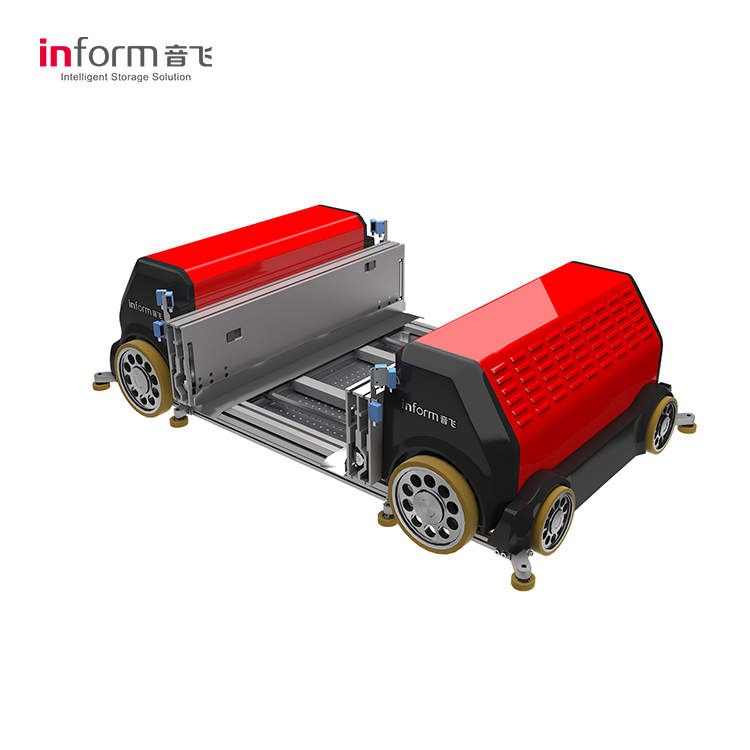

Factory selling Automated Pallet Storage Systems - Four-Way Radio Shuttle – INFORM

Overview Product Analysis ①Functions 1 Manual function Manually operate shuttle to forward, backward, jacking, putting down, transfer direction, etc. by testing software. 2 Automatic in and out Four-way shuttle performs inbound and outbound operation for pallets by scheduling software. 3 Automatic shifting Four-way shuttle shifts pallets from one position to specified one in another lane by scheduling software. 4 Counting Automatically count the number of lane’s pallet, a... -

-

High Quality Automated Racking System – Giraffe Series Stacker Crane – INFORM

Product Details Giraffe Product Analysis: Name Code Standard value(mm)(detailed data is determined according to the project situation) Cargo width W 400 ≤W ≤2000 Cargo depth D 500 ≤D ≤2000 Cargo height H 100 ≤H ≤2000 Total height GH 24000<GH ≤35000 Top ground rail end length F1, F2 Confirm according to the specific plan Outer width of stacker crane A1, A2 Confirm according to the specific plan Stacker crane distance from the end A3, A4 Confirm according to ... -

One of Hottest for Warehouse Shelving - Drive In Racking – INFORM

Racking Components Product Analysis Racking type: Drive in racking Material: Q235/Q355 Steel Certificate CE, ISO Size: customized Loading: 500-1500kg/pallet Surface treatment: powder coating/galvanized Color: RAL color code Pitch 75mm Place of origin Nanjing, China Application: big batch and less variety cargos, like food, tobacco and freezer. ① High utilization of warehouse space Compared with selective pallet rack, drive in utilizes 80% of storage space by elimin... -

-

-

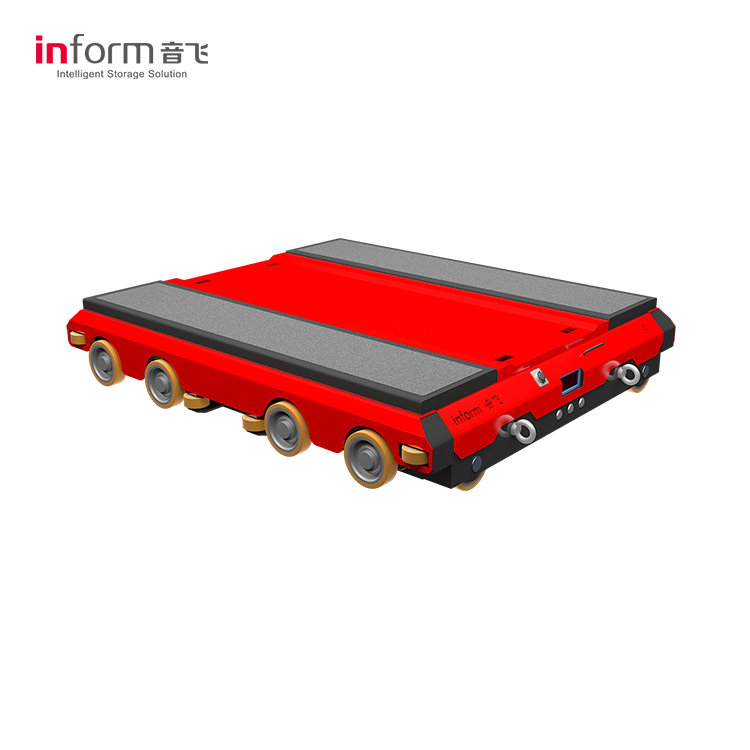

Hot New Products Automated Cranes - Shuttle Mover – INFORM

Overview Product Analysis ①Functions 1 Pallet conveying Independent pallet conveying capability, shuttle mover and radio shuttle work individually in fast operation. 2 Charging online Multi-level power threshold control, self-judging and self-charging on line. 3 Remote control One press to switch online and manual operation on remote control mode (optional) 4 System monitoring Monitoring system data in real time and alarm in sound and light in abnormal status 5 Heartbea... -

-

High Quality Automated Racking System – Lion Series Stacker Crane – INFORM

Product Details Product Analysis: Name Code Standard value(mm)(detailed data is determined according to the project situation) Cargo width W 400 ≤W ≤2000 Cargo depth D 500 ≤D ≤2000 Cargo height H 100 ≤H ≤2000 Total height GH 3000<GH ≤24000 Top ground rail end length F1、F2 Confirm according to the specific plan Outer width ofstacker crane A1、A2 Confirm according to the specific plan Stacker crane distance from the end A3、A4 Confirm according to t... -

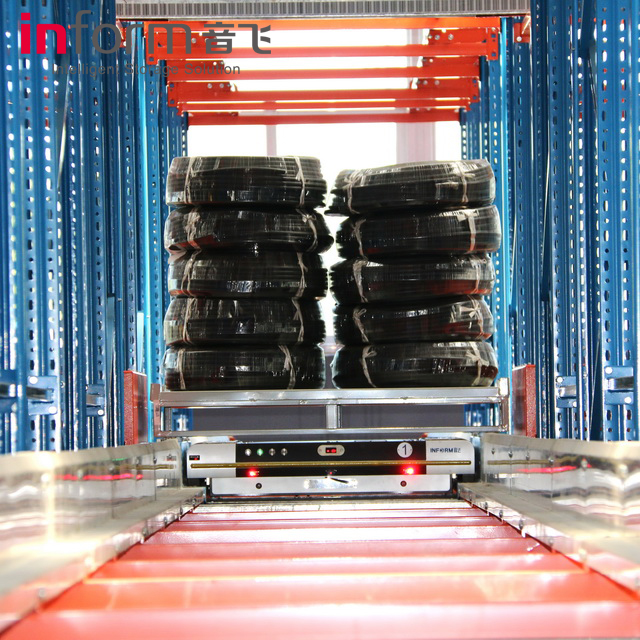

Special Design for Palletizing Equipment - Radio Shuttle – INFORM

Overview Product Analysis ①Functions 1 Automatic single inbound Accepting inbound instruction, shuttle lifts goods at the inbound end and places it on empty position then returns. 2 Automatic single outbound After accepting outbound instruction, shuttle automatically takes the stored pallet in lane to outbound or shuttle mover. 3 Continuous inbound and outbound For continuous inbound and outbound task in batch, the number to be operated can be set on remote control, mobil...