Factory supplied Selective Racking - Drive In Racking – INFORM

Factory supplied Selective Racking - Drive In Racking – INFORM Detail:

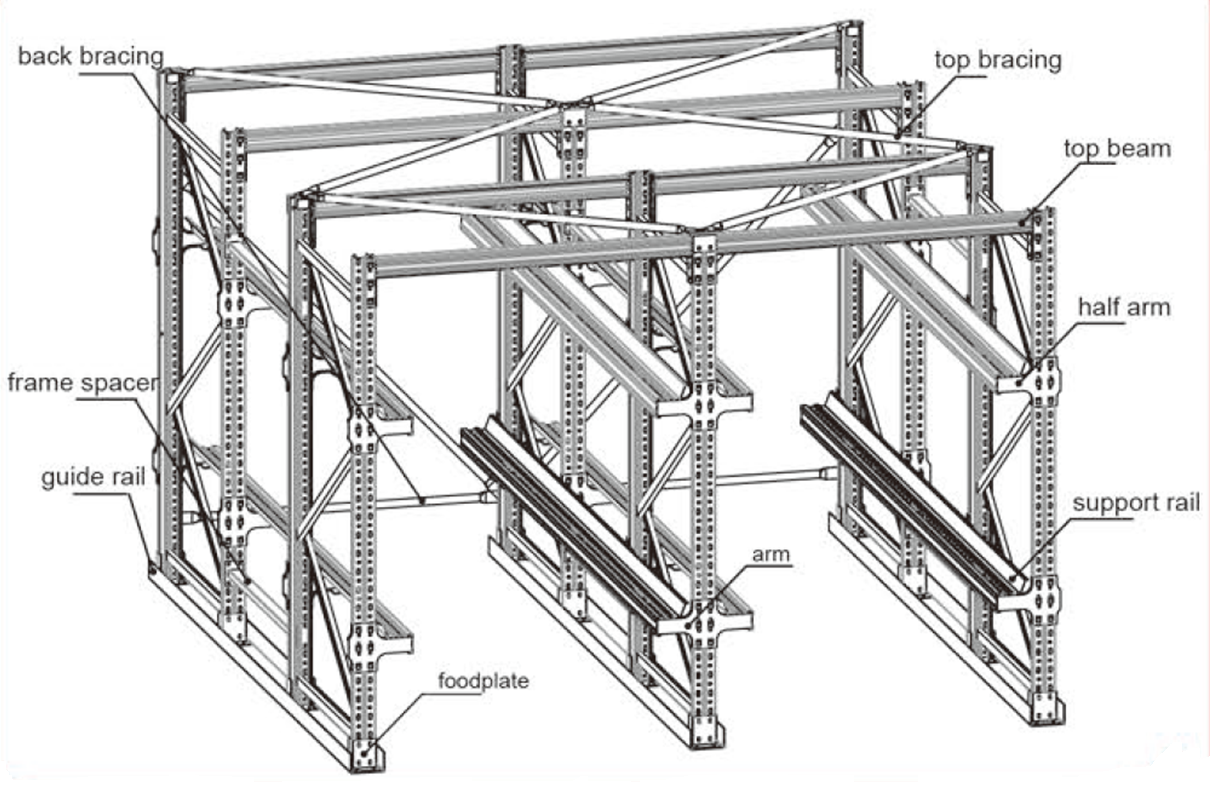

Racking Components

Product Analysis

| Racking type: | Drive in racking | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 500-1500kg/pallet |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 75mm | Place of origin | Nanjing, China |

| Application: | big batch and less variety cargos, like food, tobacco and freezer. | ||

① High utilization of warehouse space

Compared with selective pallet rack, drive in utilizes 80% of storage space by eliminating aisles, making warehouse space utilization rate increasing by 40%.

② Adjustable storage height and depth

Drive in racking can be set up to 8 pallets depth and 10m high. But the most recommended design is 4-5 pallets depth and 4 levels high for safe loading/unloading and convenient management.

③ Cold room

Due to the high density that drive in racking system provide, it is ideal for storage at low temperature in cold room. Since coolers and freezers are expensive property, getting the most storage capacity and highest efficiency are priority. It is an excellent solution for cold room storage.

④ Drive in and Drive through

Drive in racking is FILO(first in last out) racking type, requiring loading and retrieving from the same side. It can be extended to another structure—Drive through racking.

Drive through can realize FIFO(first in first out) purpose by removing back bracing, so loading is from one side and unloading is from the other. The advantage is that storage capacity is increased again, while the disadvantage is that racking stability is reduced without back bracing.

Project cases

Why choose us?

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for Factory supplied Selective Racking - Drive In Racking – INFORM, The product will supply to all over the world, such as: California, Belize, Montpellier, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!