Factory Promotional Conventional Pallet Racking - AS/RS Racking – INFORM

Factory Promotional Conventional Pallet Racking - AS/RS Racking – INFORM Detail:

Racking Components

Product Analysis

| Racking type: | AS/RS (Automated Storage and Retrieval System) | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 1000-3000kg/pallet |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 75mm | Place of origin | Nanjing, China |

| Application: | industrial production, logistics, commodity manufacturing , military applications industries | ||

① High space Utilization

The space utilization of AS/RS is 2-5 times than common storage. The racking can be designed as single-depth or double-depth to improve storage capacity, also compatible with any size pallet.

② Improving efficiency of storage and picking

AS/RS is dynamic storage and advanced logistics system, improving production management level. Compared with static racking system, the storage and picking efficiency is much improved.

③ Labor-saving operation

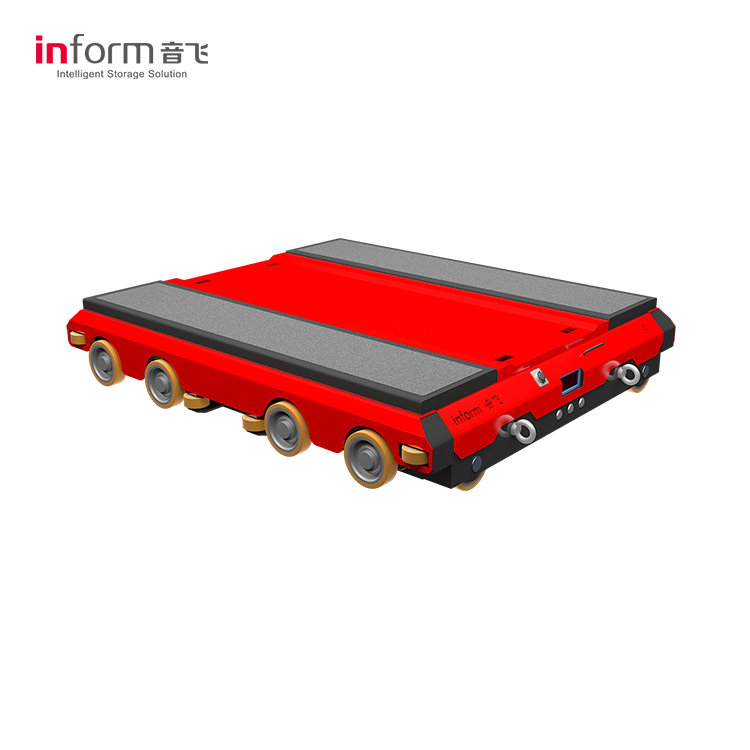

The pallet moving is handled by equipment, and controlled by software system. So it requires minimum labor and allows to operate unattended around the clock.

④Mini Load AS/RS

In addition to regular pallet storage, there is the other AS/RS racking type, suitable for carton/box/bin storage, called Mini Load AS/RS. Similar as AS/RS, mini load is a combination of shelving, equipments and software system.

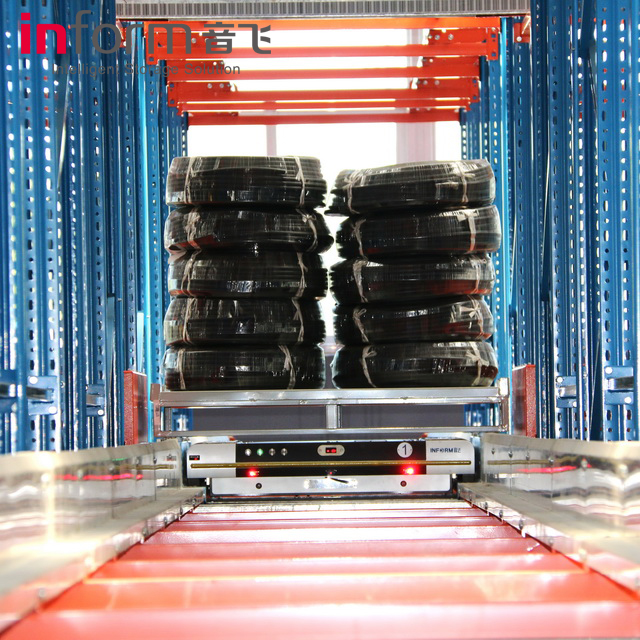

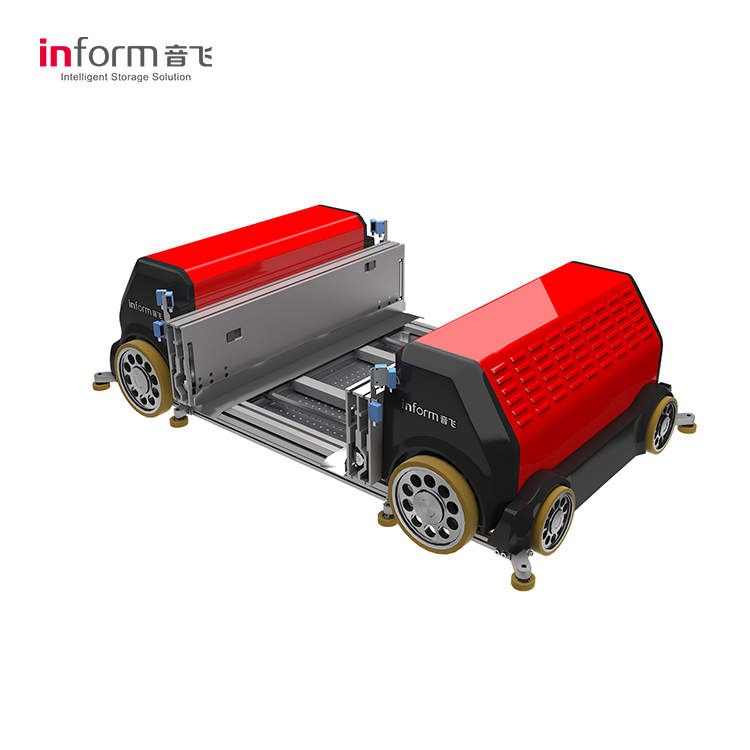

⑤ High adaptability with other automated storage robots

AS/RS is able to work with other automated storage robots, like shuttle car, shuttle mover, four way shuttle and so on, to meet diversified storage requirement and increase efficiency.

Project cases

Industry: Paper / Pallet Positions: around 60,000 / Height: 24m

Industry: Soy Sauce Pallet Positions: around 31,000 Height: 32m

Industry: Industry: Ceramics Pallet Positions: around 52,000 Height: 26m

Miniload ASRS racking

Industry: Garments

Carton Positions: 30,000

Height: 9m

Why choose us?

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for Factory Promotional Conventional Pallet Racking - AS/RS Racking – INFORM, The product will supply to all over the world, such as: Greek, United States, Saudi Arabia, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!