Factory making Warehouse Racking - Drive In Racking – INFORM

Factory making Warehouse Racking - Drive In Racking – INFORM Detail:

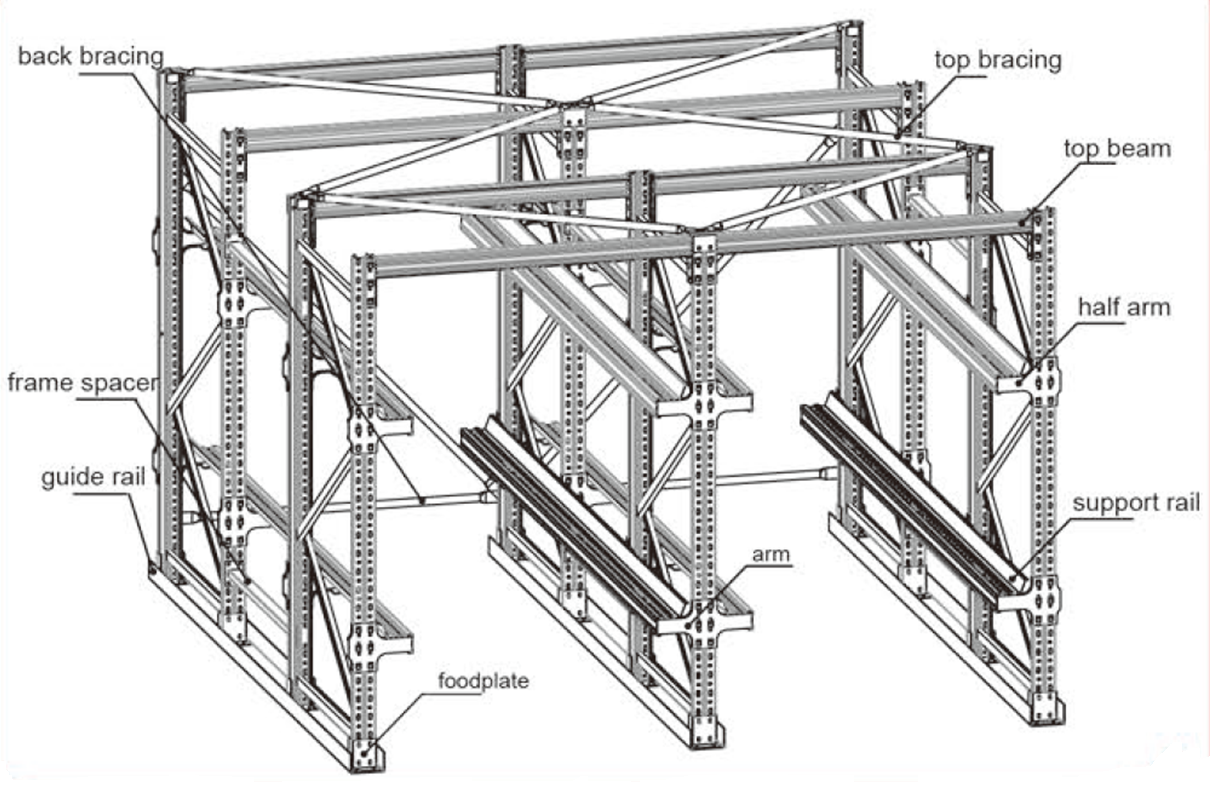

Racking Components

Product Analysis

| Racking type: | Drive in racking | ||

| Material: | Q235/Q355 Steel | Certificate | CE, ISO |

| Size: | customized | Loading: | 500-1500kg/pallet |

| Surface treatment: | powder coating/galvanized | Color: | RAL color code |

| Pitch | 75mm | Place of origin | Nanjing, China |

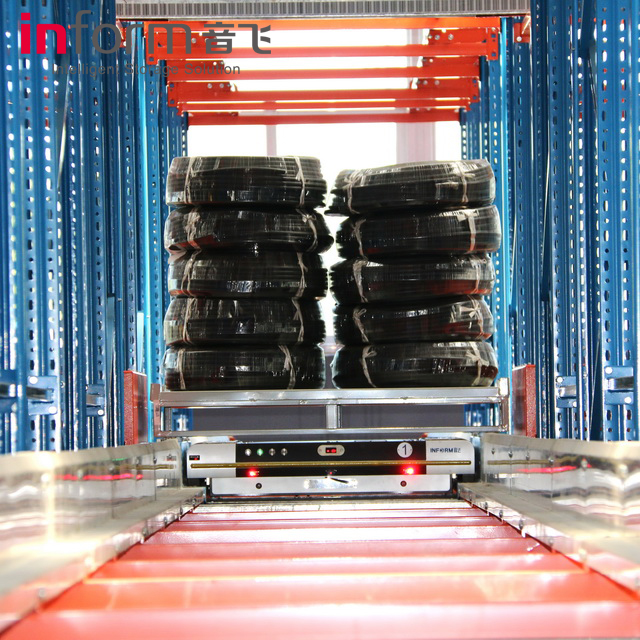

| Application: | big batch and less variety cargos, like food, tobacco and freezer. | ||

① High utilization of warehouse space

Compared with selective pallet rack, drive in utilizes 80% of storage space by eliminating aisles, making warehouse space utilization rate increasing by 40%.

② Adjustable storage height and depth

Drive in racking can be set up to 8 pallets depth and 10m high. But the most recommended design is 4-5 pallets depth and 4 levels high for safe loading/unloading and convenient management.

③ Cold room

Due to the high density that drive in racking system provide, it is ideal for storage at low temperature in cold room. Since coolers and freezers are expensive property, getting the most storage capacity and highest efficiency are priority. It is an excellent solution for cold room storage.

④ Drive in and Drive through

Drive in racking is FILO(first in last out) racking type, requiring loading and retrieving from the same side. It can be extended to another structure—Drive through racking.

Drive through can realize FIFO(first in first out) purpose by removing back bracing, so loading is from one side and unloading is from the other. The advantage is that storage capacity is increased again, while the disadvantage is that racking stability is reduced without back bracing.

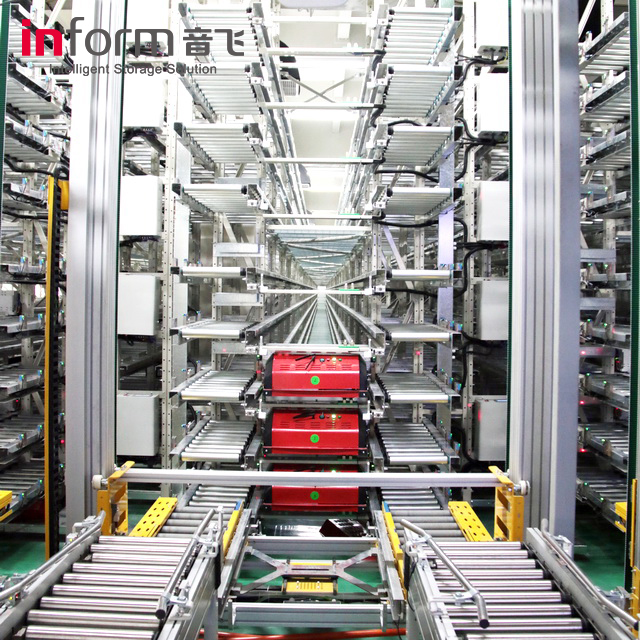

Project cases

Why choose us?

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for Factory making Warehouse Racking - Drive In Racking – INFORM, The product will supply to all over the world, such as: Jamaica, Armenia, Zimbabwe, Although continuous opportunity, we have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.